China Cold Drawn Welded Tubes Manufacturer | Quality & Precision Products

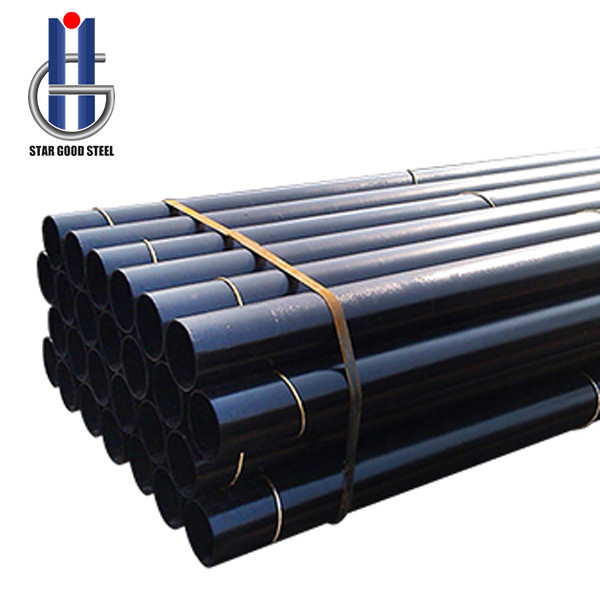

When you need reliable and high-quality Cold Drawn Welded Tubes, I invite you to explore options from trusted manufacturers in China. Our products are crafted to meet rigorous industry standards, ensuring that they perform exceptionally in various applications. Each tube goes through a meticulous manufacturing process, guaranteeing durability and precision. I understand that sourcing the right materials is crucial for your business success. That’s why our Cold Drawn Welded Tubes are not just robust, but designed to enhance efficiency in your projects. With a variety of sizes and specifications available, we can cater to your unique requirements. Working with us means you're choosing a partner who cares about your needs and is dedicated to providing you with the best product at competitive prices. Let’s connect and see how our tubes can add value to your supply chain. Quality is just a conversation away!

Cold Drawn Welded Tubes Ahead of the Curve Winning in 2025

The landscape of the steel industry is rapidly evolving, and companies producing cold drawn welded tubes are positioned to lead the charge into 2025 and beyond. As the global demand for high-quality, durable products rises, these tubes have become essential in various applications, from automotive to construction. Their unique combination of strength, precision, and cost-effectiveness makes them an attractive choice for manufacturers seeking to optimize their supply chains and reduce overall production costs. Sustainability is at the forefront of modern manufacturing, and the production of cold drawn welded tubes aligns seamlessly with green initiatives. Advanced manufacturing techniques are being employed to minimize waste and reduce energy consumption, offering procurement managers a responsible choice without sacrificing quality. As businesses navigate increasingly stringent environmental regulations, aligning with suppliers that prioritize sustainability will be critical for long-term success. Looking ahead to 2025, the steel industry will likely face challenges such as fluctuating raw material prices and evolving customer demands. However, by investing in innovation and maintaining a strong commitment to quality, manufacturers of cold drawn welded tubes will not only meet industry expectations but will also carve out a niche in an increasingly competitive market, positioning themselves as leaders in both technology and sustainability.

Cold Drawn Welded Tubes Ahead of the Curve Winning in 2025

| Application | Material Type | Diameter (mm) | Market Growth Rate (%) | Key Regions |

|---|---|---|---|---|

| Automotive | Steel | 50 | 5.2 | North America, Europe |

| Construction | Aluminum | 75 | 6.5 | Asia-Pacific, Europe |

| Aerospace | Titanium | 40 | 7.8 | North America, Middle East |

| Oil & Gas | Carbon Steel | 60 | 4.0 | Latin America, Middle East |

| Hydraulics | Stainless Steel | 30 | 5.9 | North America, Asia-Pacific |

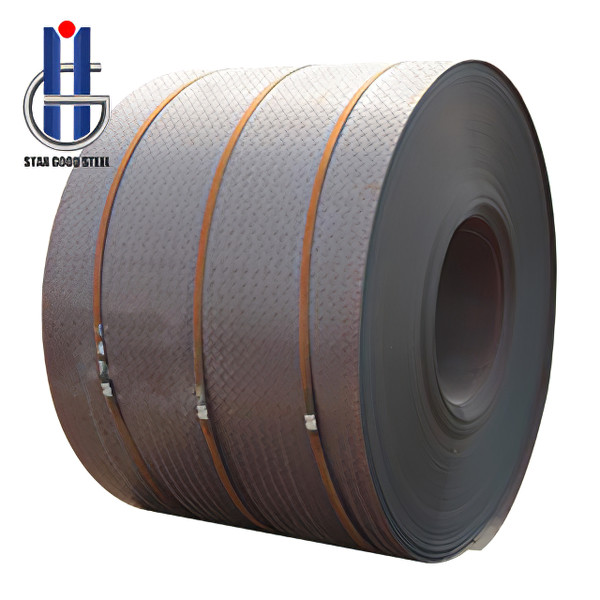

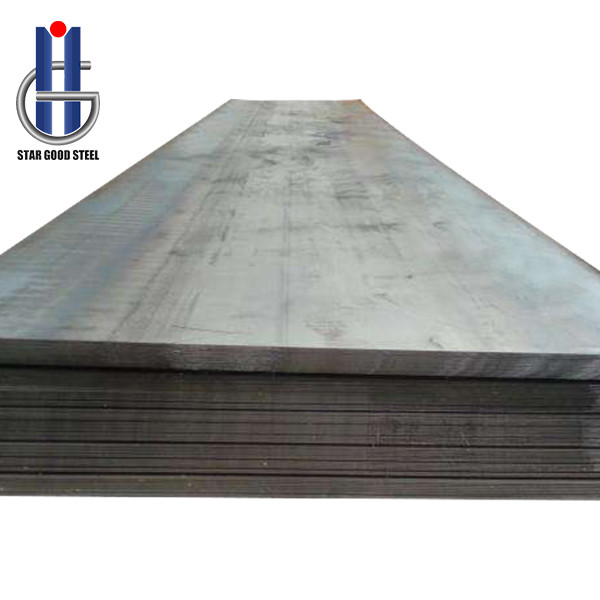

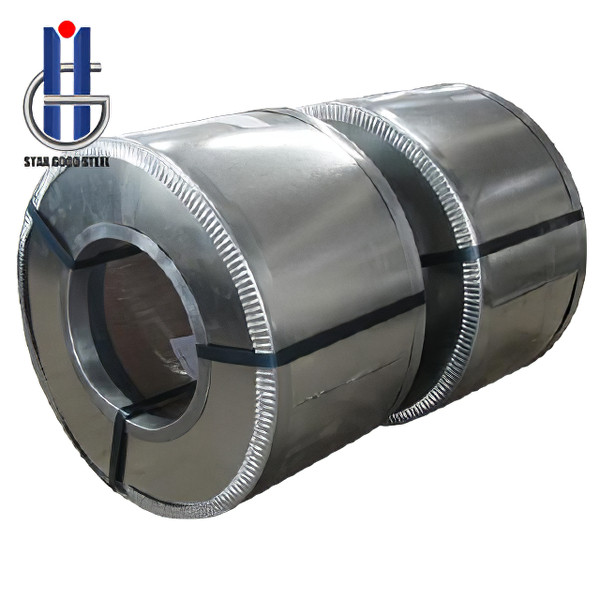

Related Products