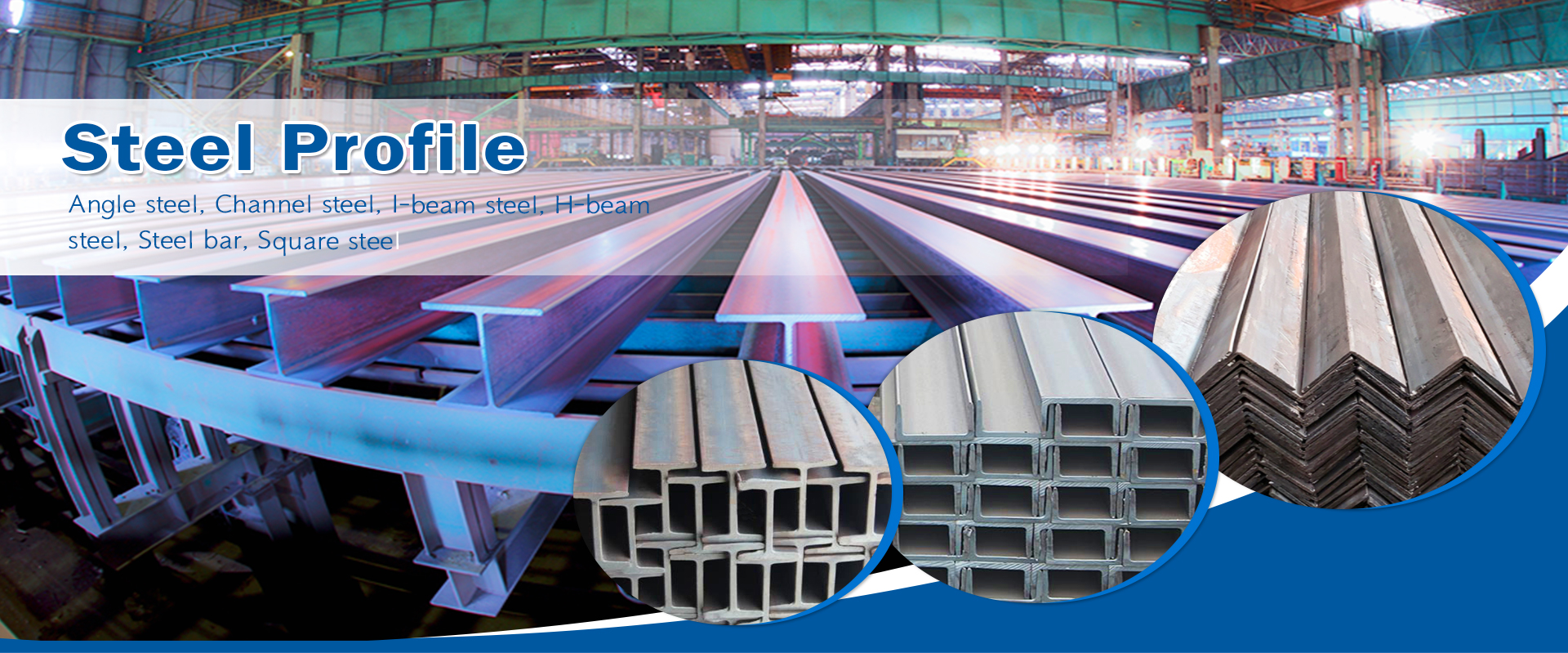

Top China Manufacturer of Spiral Welded Tube for Reliable Solutions

As a professional in the industry, I understand the value of quality when it comes to Spiral Welded Tubes. Sourced from reputable manufacturers in China, these tubes are engineered to meet rigorous standards, ensuring durability and reliability for various applications. My experience tells me that choosing the right supplier is crucial, and I have consistently seen how our tubes excel in performance and longevity. When it comes to meeting your project needs, the versatility of Spiral Welded Tubes cannot be overstated. Whether you're in construction, manufacturing, or any other sector, these tubes can play an essential role in your operations. I’ve seen firsthand how they optimize structural integrity and enhance product performance. I invite you to explore our offerings and see the difference that high-quality materials make. Our team is here to support you every step of the way, ensuring your projects are a success.

Spiral Welded Tube Ahead of the Curve Supplies the World\u2019s Top Brands

In the highly competitive landscape of manufacturing and supply, spiral welded tubes have emerged as a vital component for industries worldwide. With their unique manufacturing process and versatility, these tubes not only provide remarkable strength but also offer exceptional resistance to external pressures and corrosion—making them ideal for various applications in oil and gas, construction, and infrastructure projects. A sophisticated understanding of this technology can significantly benefit global buyers seeking reliable and innovative solutions. Our commitment to quality and efficiency ensures that our spiral welded tubes meet the stringent standards required by some of the world's leading brands. By adopting advanced manufacturing techniques and continuous improvement practices, we deliver products that excel in performance and longevity. Our adherence to international quality certifications further guarantees that our tubes are crafted with precision, resulting in enhanced structural integrity and reliability for our customers. As global demand for high-quality, durable materials continues to rise, we stand at the forefront of innovation, ready to meet the challenges of various industries. Collaborating closely with partners and clients, we strive to provide tailored solutions that not only satisfy immediate needs but also foster long-term relationships built on trust and excellence. Embrace the potential of spiral welded tubes and elevate your project outcomes with cutting-edge materials that support your strategic goals.

Spiral Welded Tube Ahead of the Curve Supplies the World’s Top Brands

| Dimension (mm) | Material Type | Applications | Certification Standards | Production Capacity (tons/year) |

|---|---|---|---|---|

| 100 x 5 | Carbon Steel | Construction | ISO 9001 | 5000 |

| 150 x 6 | Stainless Steel | Oil & Gas | ASTM A312 | 3000 |

| 200 x 8 | Alloy Steel | Shipbuilding | DNV GL | 4000 |

| 250 x 10 | Galvanized Steel | Automotive | ISO/TS 16949 | 3500 |

| 300 x 12 | Seamless Steel | Pipelines | API 5L | 2000 |

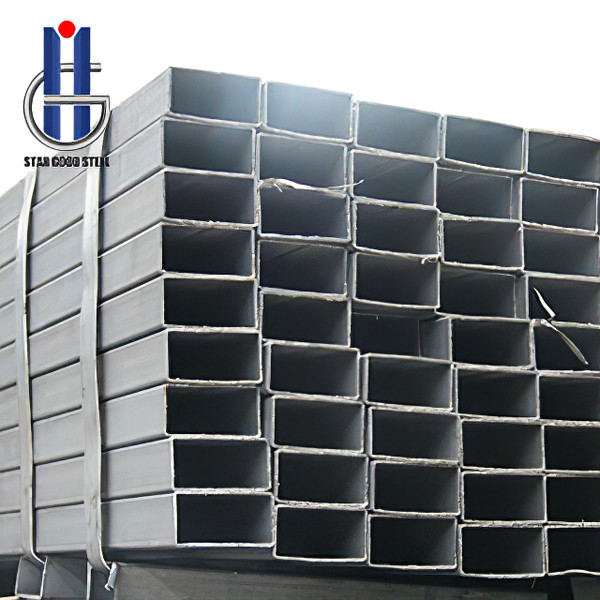

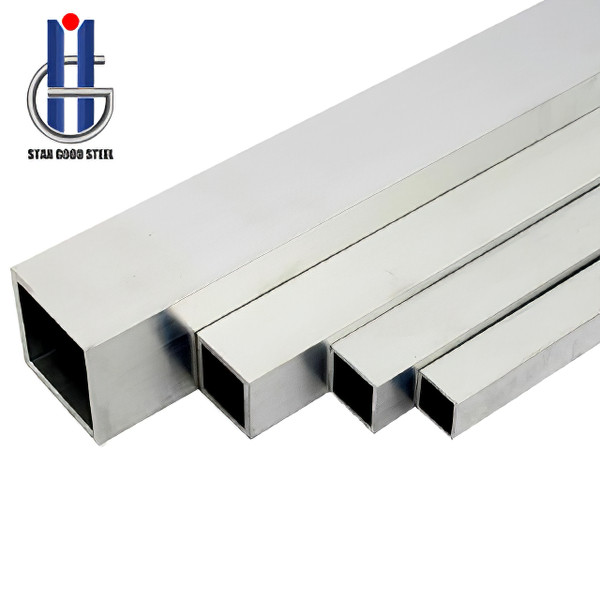

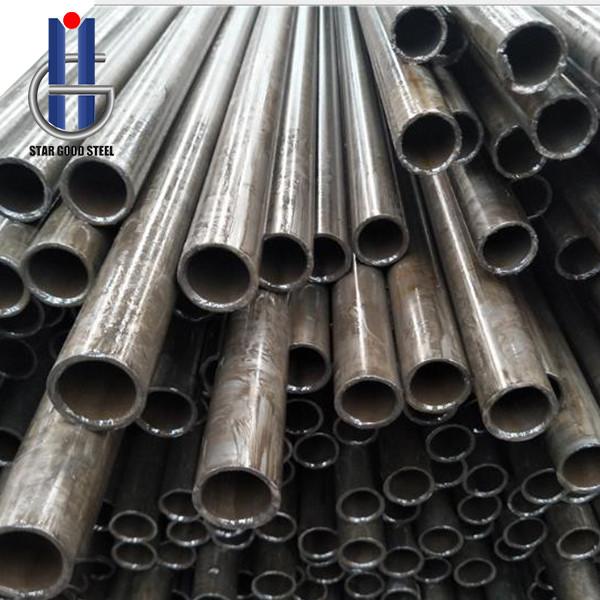

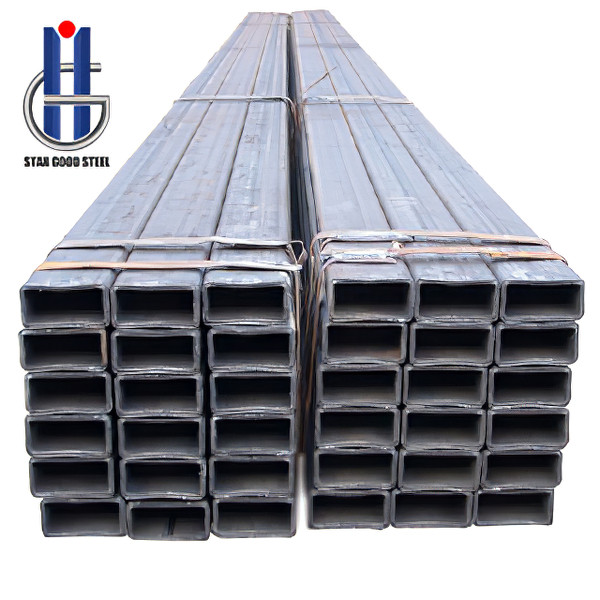

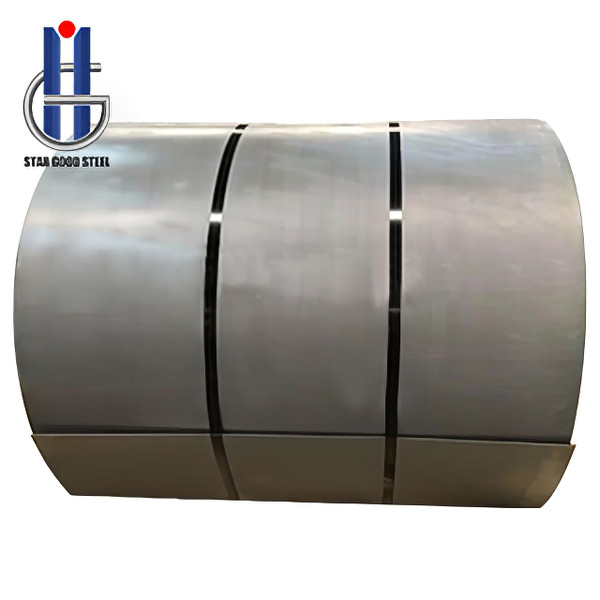

Related Products