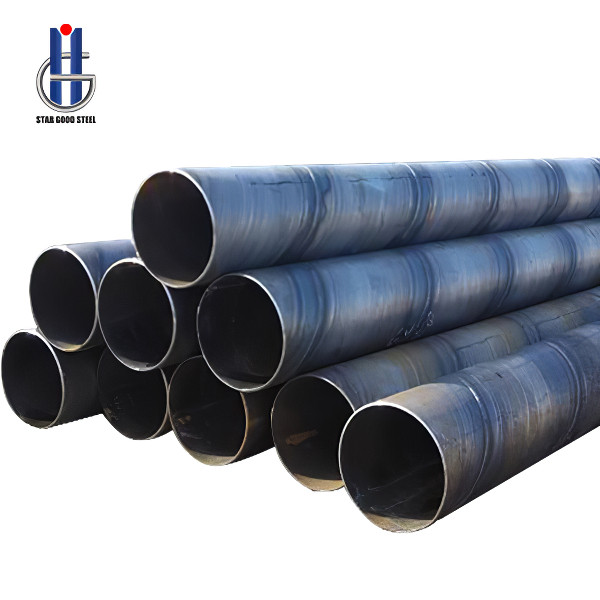

Top China Manufacturer of Cold Rolled Seamless Steel Tubes

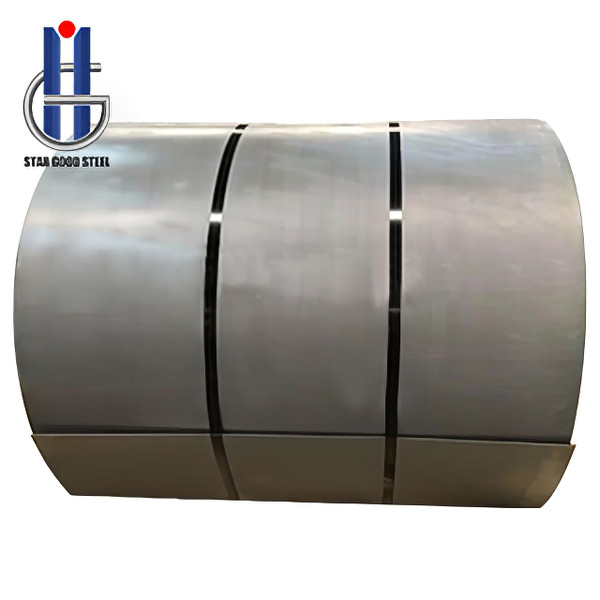

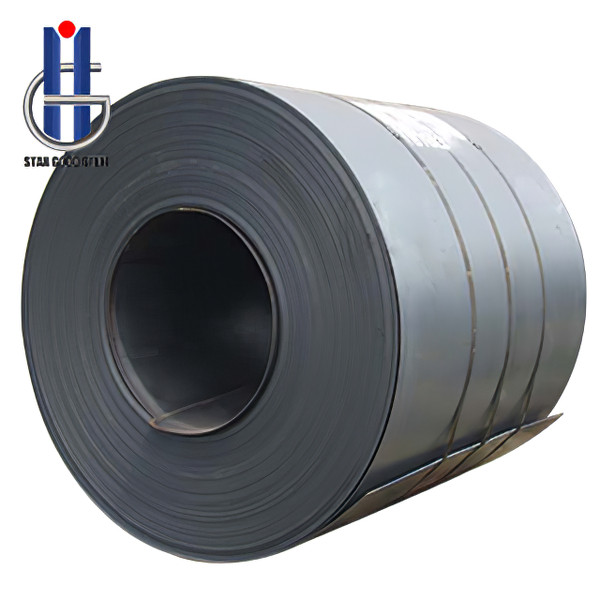

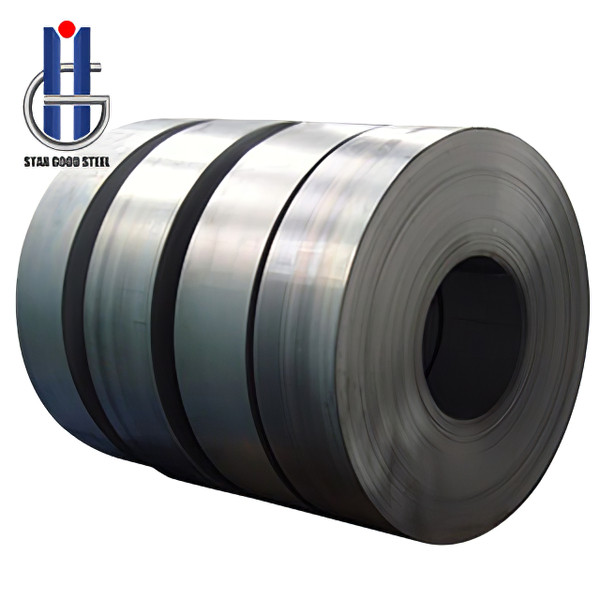

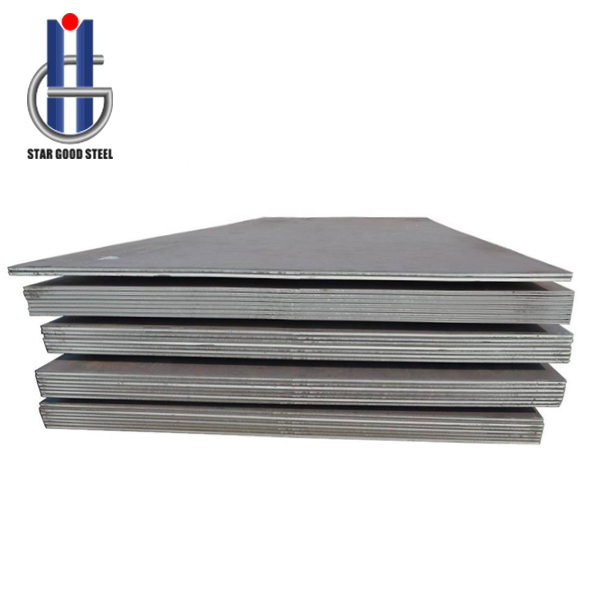

When it comes to sourcing high-quality cold rolled seamless steel tubes, finding a reliable manufacturer in China is crucial. We specialize in producing top-notch tubes that meet rigorous industry standards. Our commitment to excellence ensures that you receive products that are not just durable, but also precise in dimensions, perfect for various applications. I understand the challenges businesses face when sourcing seamless steel solutions, and we aim to simplify that process for you. Our manufacturing facility is equipped with advanced technology, allowing us to maintain consistency and efficiency in production. Partnering with us means you're investing in reliable materials that guarantee performance. Whether you’re in construction, automotive, or any sector needing seamless tubes, our products cater to your needs. Let's work together to fulfill your project requirements with the strength and quality you expect from a top-tier supplier. Reach out today for a competitive quote and exceptional service!

Cold Rolled Seamless Steel Tube Factory For the Current Year From Concept to Delivery

In the ever-evolving landscape of manufacturing, the journey from concept to delivery of cold rolled seamless steel tubes has become increasingly significant. This year presents an array of opportunities for global procurement professionals seeking reliable and high-quality steel products. The manufacturing process involves meticulous planning and execution, ensuring that each stage, from raw material selection to final delivery, adheres to rigorous quality standards. Advanced techniques in metallurgy and precision engineering result in seamless tubes that meet diverse industrial requirements, from construction to automotive applications. As manufacturers, we are committed to innovation and excellence, continually optimizing our production processes to enhance efficiency and minimize lead times. By leveraging state-of-the-art technology and a skilled workforce, we can provide seamless steel tubes that not only meet but exceed international specifications. Furthermore, our emphasis on sustainable practices ensures that our production processes are environmentally friendly, which is increasingly important to global buyers mindful of their own sustainability goals. In addition to quality and innovation, understanding the needs of our clients is paramount. We foster strong relationships with our global partners through transparent communication and dedicated support throughout the procurement process. By aligning our offerings with market demands, we ensure that our clients receive the right products at the right time, building trust and enabling long-term partnerships. Whether you are looking for standard solutions or customized products, this year marks an exciting time to explore the potential of cold rolled seamless steel tubes for your business.

Cold Rolled Seamless Steel Tube Factory For the Current Year From Concept to Delivery

| Process Stage | Description | Duration (days) | Responsible Department | Quality Check |

|---|---|---|---|---|

| Design | Initial designs and specifications of the steel tube. | 10 | Engineering | Yes |

| Material Selection | Choosing appropriate raw materials for production. | 5 | Procurement | Yes |

| Manufacturing | Production of seamless steel tubes through cold rolling. | 15 | Production | Yes |

| Quality Control | Inspection of finished products for quality assurance. | 7 | Quality Assurance | Yes |

| Packaging | Preparing products for shipment. | 3 | Logistics | Yes |

| Delivery | Shipping products to customers. | 5 | Logistics | N/A |

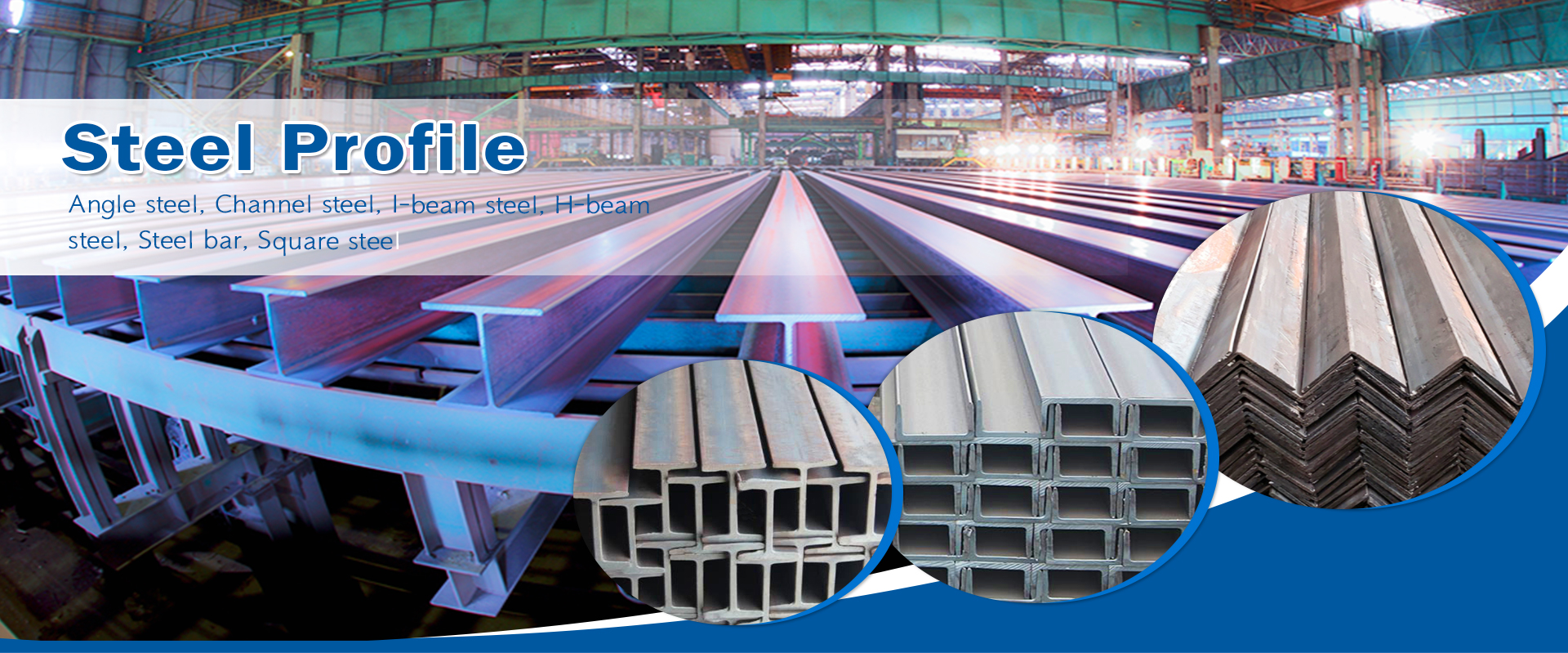

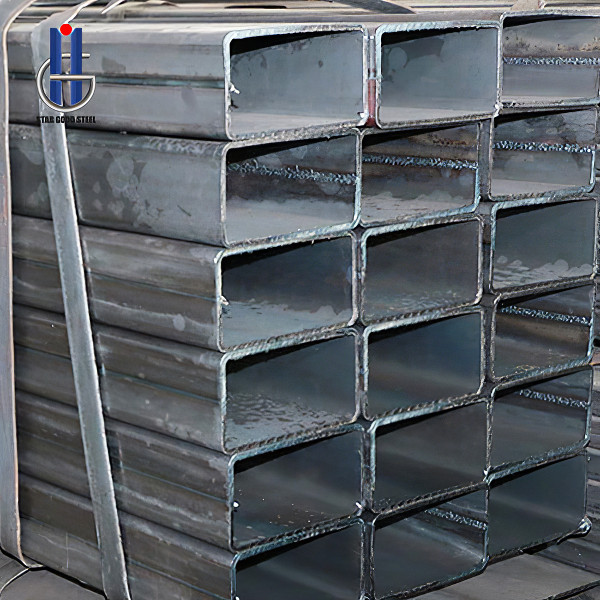

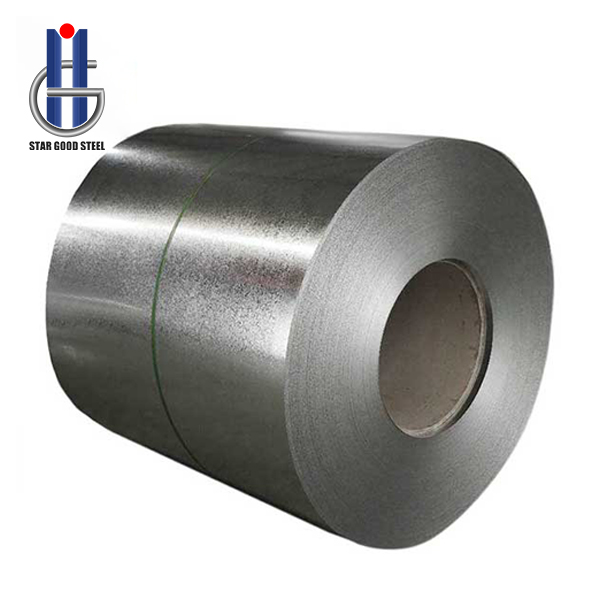

Related Products