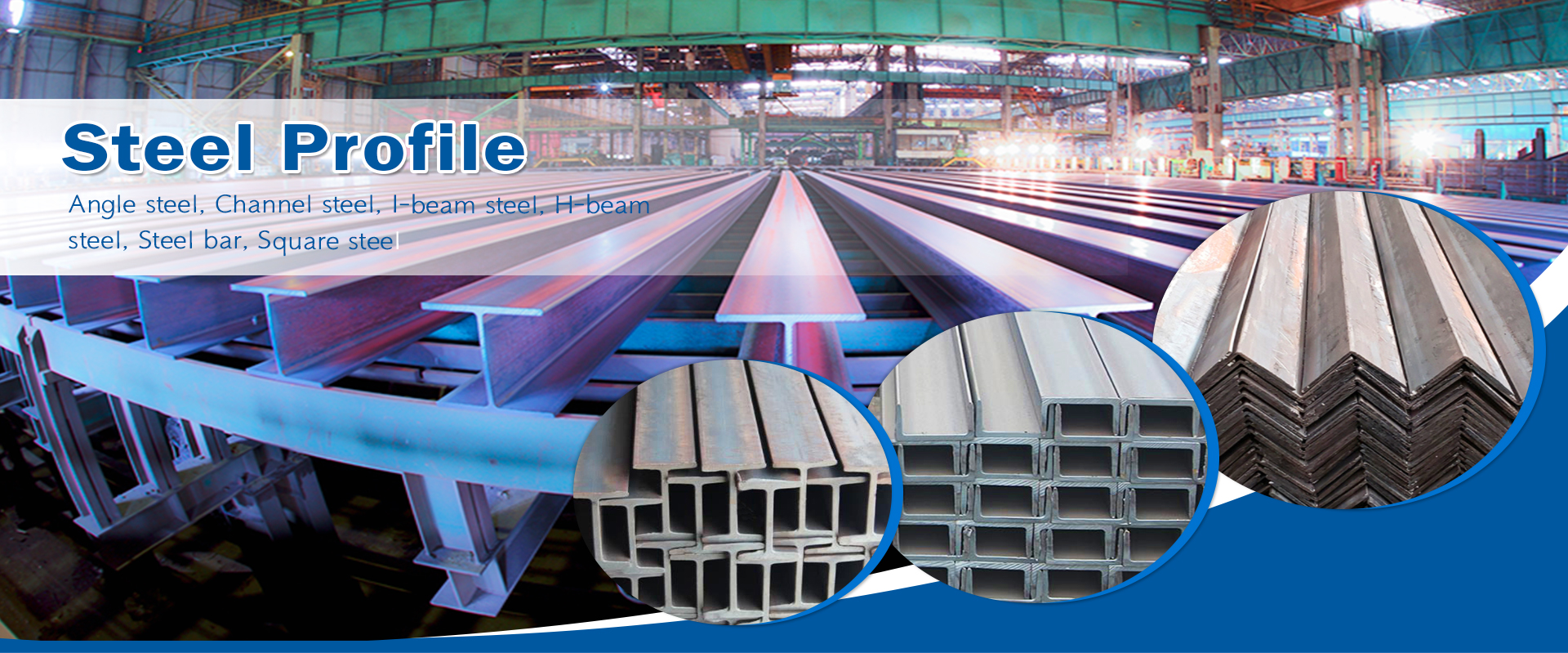

Top China Manufacturer of Cold Rolled Steel Square Tube - Quality Products

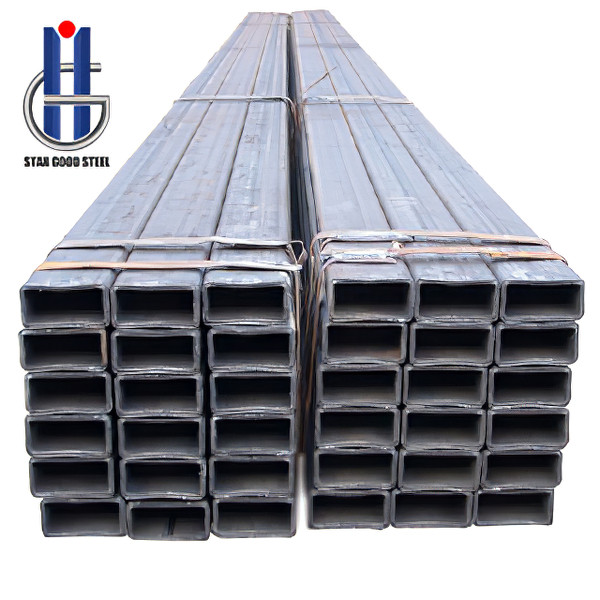

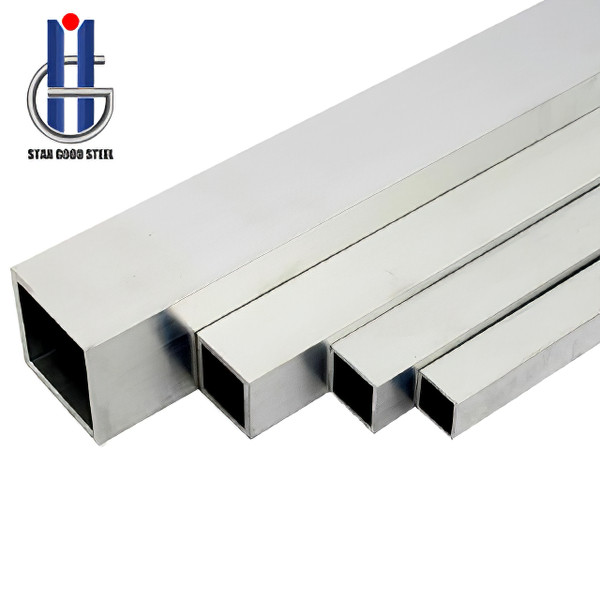

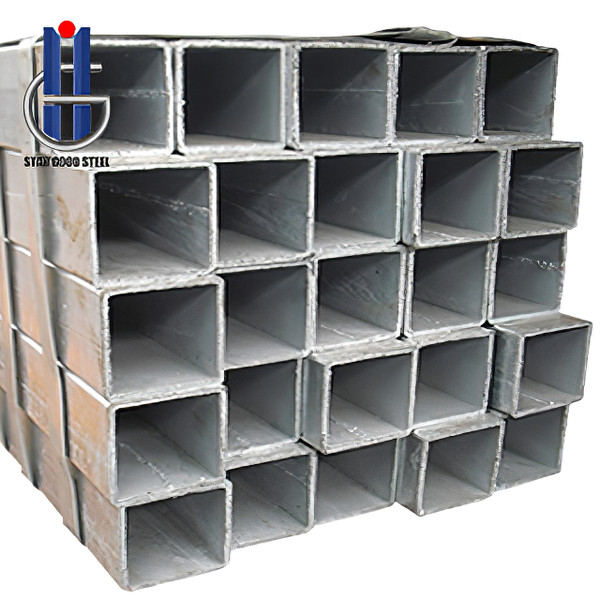

As a supplier of Cold Rolled Steel Square Tubes, I understand the importance of quality and reliability in your projects. Sourced directly from trusted manufacturers in China, our steel tubes are crafted to meet the highest industry standards. Each tube features precise dimensions and superior strength, making them ideal for various applications, from construction to automotive. What sets our products apart is not just the material but the commitment to excellence. I prioritize ensuring that you receive consistency and durability in every order. My team works closely with manufacturers to guarantee that you get the best possible products on the market. Whether you’re looking to enhance your supply chain or need a dependable source for your ongoing projects, our Cold Rolled Steel Square Tubes can be a great fit. Let’s connect and see how I can help fulfill your requirements!

Cold Rolled Steel Square Tube Factory For the Current Year

In the current year, the demand for cold rolled steel square tubes continues to rise globally, driven by various industries such as construction, automotive, and manufacturing. These versatile tubes are highly sought after for their strength, durability, and precision. As buyers look for quality and reliable sources, understanding the production processes and quality assurance measures adopted by manufacturers becomes increasingly crucial. Cold rolled steel square tubes are produced through a method that enhances the mechanical properties of the steel, resulting in strong and uniform products that meet specific industry standards. This manufacturing technique involves rolling the steel at ambient temperatures, which leads to improved tolerance and a finer surface finish compared to hot rolled alternatives. For global procurement specialists, partnering with manufacturers that utilize advanced technology and adhere to strict quality control processes ensures a steady supply of high-performance steel products. Moreover, as sustainability becomes a central theme in global trade, buyers are encouraged to consider suppliers who prioritize eco-friendly practices in their production. By opting for manufacturers that implement green technologies and recycling initiatives, procurement teams not only contribute to environmental stewardship but also enhance their corporate responsibility image. In this competitive market, focusing on quality, sustainability, and reliable delivery will empower procurement professionals to make informed decisions that align with their organizational goals.

Cold Rolled Steel Square Tube Factory For the Current Year

| Material Grade | Dimensions (mm) | Application | Production Capacity (tons/month) | Lead Time (weeks) |

|---|---|---|---|---|

| Q235 | 20 x 20 x 1.5 | Construction, Automotive | 300 | 4 |

| ST37 | 25 x 25 x 2.0 | Machinery, Steel Structure | 250 | 6 |

| S355 | 30 x 30 x 3.0 | Structural, Heavy Equipment | 200 | 5 |

| A500 | 40 x 40 x 4.0 | Furniture, Railing | 150 | 3 |

| A36 | 50 x 50 x 5.0 | Construction, Manufacturing | 100 | 4 |

Related Products