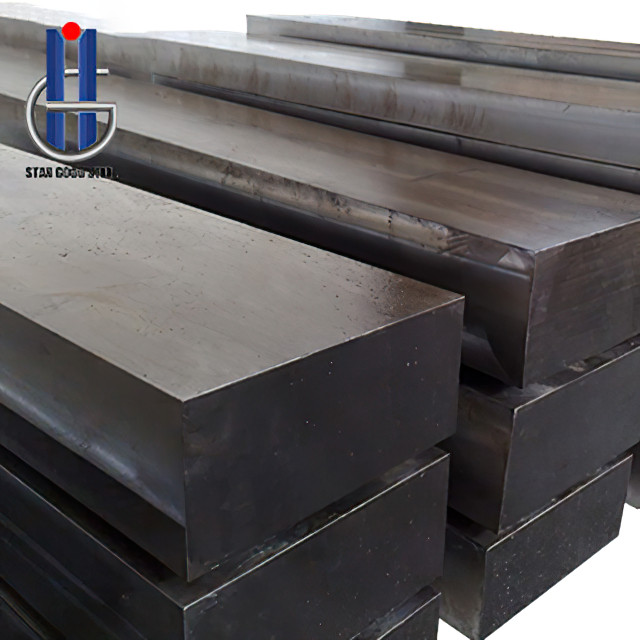

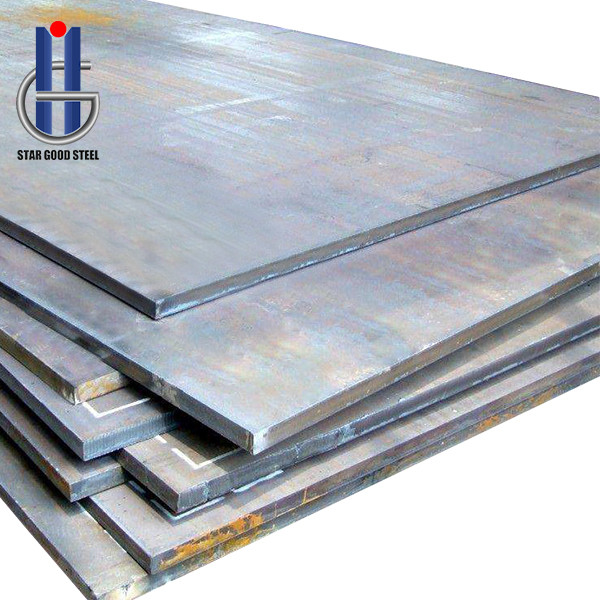

Top China Manufacturer of Hot Rolled Die Steel for High-Performance Tools

When I think about high-quality hot rolled die steel, I can't help but emphasize its importance in industrial applications. Sourced from reliable manufacturers in China, our hot rolled die steel provides exceptional durability and resistance under extreme conditions. This product is ideal for industries involved in heavy machinery, automotive parts, and precision tooling. Our hot rolled die steel offers superior hardness and wear resistance, ensuring longevity even in the most demanding environments. I understand that as a B2B purchaser, you need materials that not only meet industry standards but also enhance your production line efficiency. By choosing our hot rolled die steel, you’re investing in a dependable solution that drives performance and productivity. With our competitive pricing and commitment to quality, you won't just be getting a product; you'll be gaining a partner in your manufacturing journey. Reach out today to explore how our steel can meet your specific needs!

Hot rolled die steel For the Current Year Ahead of the Curve

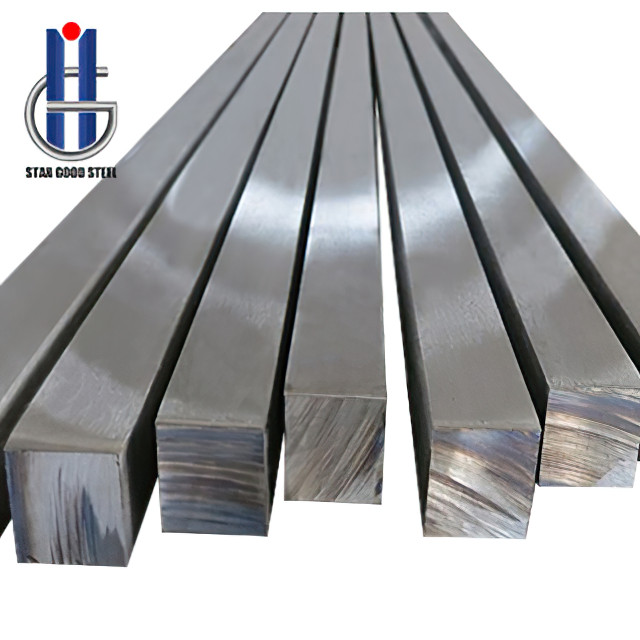

In the evolving landscape of industrial materials, hot rolled die steel stands out as a pivotal choice for manufacturers seeking durability and precision. As we step into the current year, it’s essential for global buyers to stay ahead of the curve by understanding the latest advancements and trends in this critical material. Hot rolled die steel is renowned for its superior mechanical properties, making it ideal for high-stress applications in various sectors such as automotive, aerospace, and tooling. Innovations in the production processes of hot rolled die steel have led to enhanced performance characteristics, including improved hardness and wear resistance. These advancements provide manufacturers with materials that not only meet but exceed stringent performance demands. Moreover, the focus on sustainable production practices is reshaping the availability and sourcing of this material, allowing buyers to align their procurement strategies with environmental goals. As the market becomes increasingly competitive, staying informed about the latest developments in hot rolled die steel is crucial for global purchasers. Collaborating with reliable suppliers who prioritize quality and innovation can significantly impact operational efficiency and product longevity. Embracing these materials now will set the foundation for successful projects in the year ahead, ensuring manufacturers can deliver exceptional results.

Hot Rolled Die Steel For the Current Year Ahead of the Curve

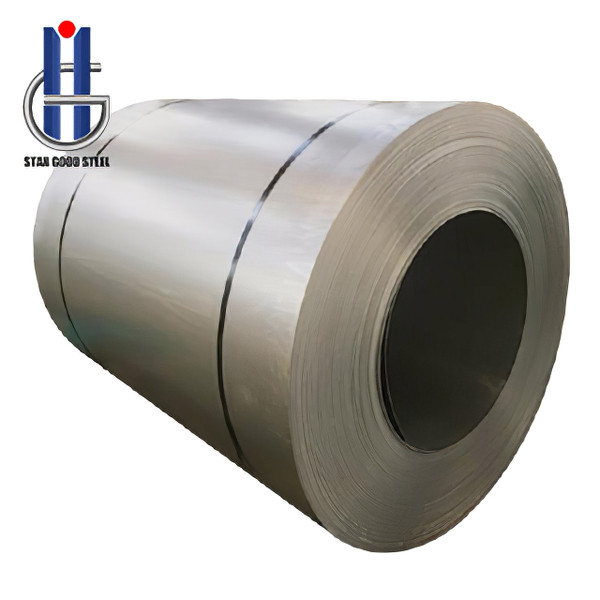

| Material Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Applications |

|---|---|---|---|---|

| H13 | 1200 | 1050 | 50 | Die casting, forging |

| D2 | 1100 | 900 | 60 | Cold work tools, dies |

| P20 | 950 | 800 | 35 | Injection molds |

| A2 | 1200 | 900 | 54 | Cutting tools, shafts |

| S7 | 1400 | 1100 | 60 | Shock resistant tools |

Related Products