What is Galvanized Steel Coil?

Galvanized steel coil is coated with a layer of zinc on the surface of the steel plate to prevent the surface from being corroded due to external factors and prolong the service life of the steel plate.

Galvanized classification:

There are mainly electro-galvanized, hot-dip galvanized and galvanized.

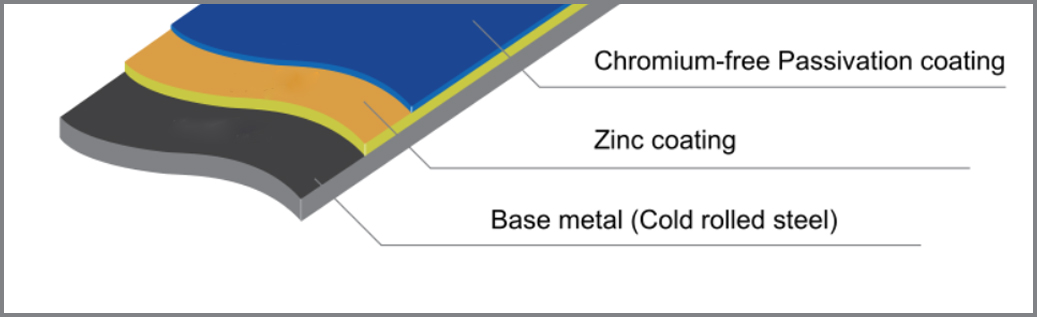

Schematic diagram of galvanized coil:

Surface structure:

large spangles small zinc flower no zinc flower

What is a large spangle? What is a small spangle?

Answer: The big spangle is the normal spangle, which can be produced according to the normal production process. The diameter of the crystal nucleus is not less than 0.2mm; the diameter of the crystal nucleus is less than 0.2mm, which is called the small spangle.

What are the main reasons for the peeling of the zinc layer?

The main reasons for the peeling of the zinc layer are: surface oxidation, silicon compounds, cold rolling emulsion too dirty, NOF section oxidizing atmosphere and protective gas dew point too high, unreasonable air-fuel ratio, low hydrogen flow, furnace oxygen infiltration, strip steel The temperature of entering the pot is too low, the furnace pressure in the RWP section is too low, the furnace door suction is too low, the furnace temperature in the NOF section is too low, the grease is not evaporated completely, the aluminum content of the zinc pot is too low, the unit speed is too fast, the reduction is insufficient, and the zinc solution stays in the liquid. The time is too short and the coating is too thick.

What are the causes of white rust and dark spots?

Black spots are formed by further oxidation of white rust. The main reasons for white rust are:

Poor passivation, insufficient or uneven thickness of the passivation film; no oil on the surface or residual moisture on the surface of the strip; moisture on the surface of the strip during coiling; incomplete drying of passivation; moisture or rain during transportation or storage ; The finished product is stored for too long; the galvanized sheet is in contact with or stored together with other corrosive media such as acid and alkali.

What are the methods for testing the corrosion resistance of hot-dip galvanized sheet?

There are three methods to test the corrosion resistance of hot-dip galvanized sheet: salt spray test; humidity test; erosion test.

Post time: May-28-2022