Top Stainless Steel Heat Exchange Tube Factory in China - Leading Manufacturer

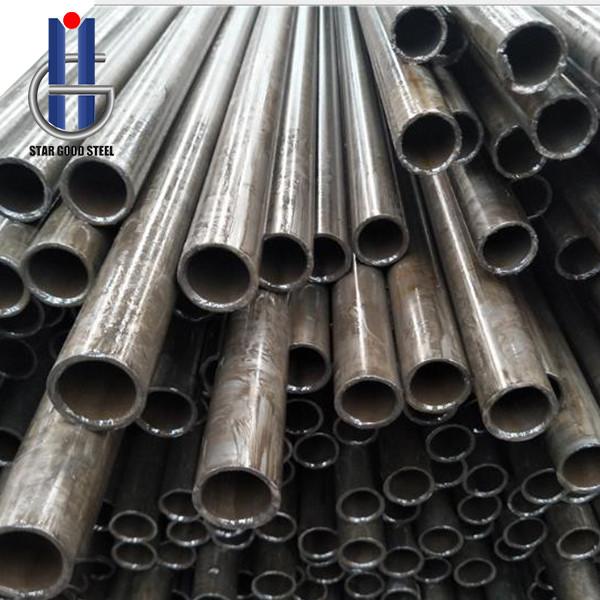

As a reliable manufacturer in China, I understand the importance of quality and efficiency in industrial applications. Our stainless steel heat exchange tubes are crafted to meet the highest standards, ensuring durability and excellent thermal performance for your processes. With a vast array of sizes and specifications available, we cater to a diverse range of needs in various industries, from petrochemical to HVAC. I take pride in focusing on precision engineering and rigorous quality control, making us a trusted choice among B2B purchasers. Our commitment to competitive pricing and timely delivery means you can count on us for your sourcing needs. If you're searching for a dependable supplier with extensive experience, our factory is dedicated to providing exceptional products that enhance your operations. Let's collaborate to find the perfect solutions tailored just for you!

Stainless Steel Heat Exchange Tube Factory Now Trending Your Trusted OEM Partner

In the realm of HVAC, petrochemical, and industrial applications, the significance of high-quality stainless steel heat exchange tubes cannot be overstated. As industries evolve and the demand for efficient thermal management solutions grows, the spotlight increasingly falls on suppliers who can deliver not just products but reliable partnerships. This is where the current trend in the market highlights the importance of choosing a trusted OEM partner that upholds stringent quality standards and innovative manufacturing practices. Enter the forefront of stainless steel heat exchange tube manufacturing. The modern factory setting is equipped with state-of-the-art technology that enables precision engineering and rigorous testing, ensuring that every tube meets the industry's stringent specifications. From seamless designs to advanced corrosion resistance, these products are not just components; they are essential elements that contribute significantly to the efficiency and longevity of complex systems. As global buyers seek sustainable solutions, tailored designs, and cost-effective options, the focus is on establishing long-term collaborations with manufacturers who prioritize excellence in every phase of production. Opting for a reputable factory as your OEM partner means access to a wealth of experience and expertise in metal fabrication. By working closely with such manufacturers, procurement professionals can benefit from customized solutions that cater to specific operational needs while maintaining high-quality output. In today's competitive landscape, aligning with a dedicated partner not only ensures the reliability of your supply chain but also positions your operations for future success amid evolving market demands.

Stainless Steel Heat Exchange Tube Factory Now Trending Your Trusted OEM Partner

| Material Grade | Outer Diameter (mm) | Wall Thickness (mm) | Length (m) | Application |

|---|---|---|---|---|

| 304 | 25 | 1.5 | 6 | Chemical Processing |

| 316 | 30 | 2.0 | 4 | Marine Applications |

| 321 | 50 | 2.5 | 8 | High-Temperature Services |

| 310 | 40 | 3.0 | 10 | Heat Exchangers |

| 409 | 20 | 1.0 | 5 | Automotive Applications |

Related Products