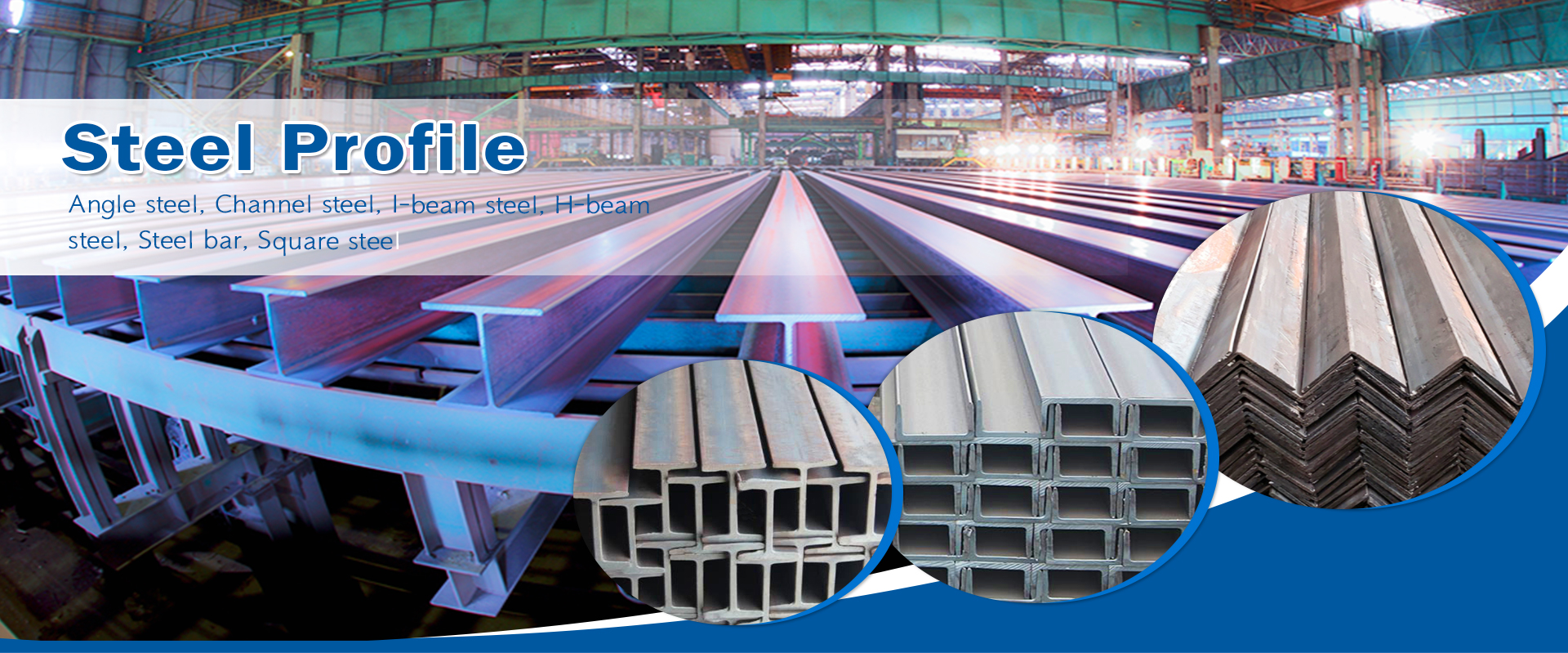

Top China Manufacturer of Stainless Steel Processing Plant Solutions

At our Stainless Steel Processing Plant in China, we specialize in delivering high-quality stainless steel products tailored to meet your unique needs. With years of experience as a leading manufacturer, we’ve honed our processes to ensure precision and durability in every item we produce. From sheet metal fabrication to custom manufacturing, our facility is equipped to handle various projects, big or small. We understand that in the competitive marketplace, quality is crucial, which is why our stainless steel undergoes rigorous testing to meet international standards. Partnering with us means you get reliable delivery times and a commitment to customer satisfaction. Whether you're in construction, automotive, or any other industry, we’re here to support your projects with the best stainless steel solutions. Reach out today to learn how we can help elevate your business with our top-notch products.

Stainless Steel Processing Plant in 2025 For the Current Year

As the global market for stainless steel continues to evolve, 2025 heralds an exciting era for stainless steel processing plants. The increasing demand for high-quality stainless steel products, driven by industries such as construction, automotive, and food processing, underscores the need for advanced processing technologies. Innovative production methods aimed at enhancing efficiency and sustainability will likely dominate the landscape, providing significant advantages to manufacturers who embrace these changes. Sustainability is becoming a key focus in steel production, with investors and consumers alike prioritizing environmentally friendly practices. By integrating renewable energy sources and recycling initiatives, stainless steel processing facilities can reduce their carbon footprint while simultaneously lowering operational costs. Furthermore, advancements in automation and artificial intelligence will enhance production efficiency and ensure consistent product quality, positioning forward-thinking companies at the forefront of the industry. For global buyers, collaborating with cutting-edge processing plants will be crucial to accessing superior stainless steel products that meet their diverse needs. As market dynamics shift, maintaining a strong supply chain with reliable partners will be essential for navigating the complexities of sourcing high-demand materials. Investing in relationships with innovative manufacturers will ensure that procurement strategies remain competitive and aligned with the future of stainless steel processing.

Stainless Steel Processing Plant in 2025 For the Current Year

| Dimension | Value | Unit |

|---|---|---|

| Annual Production Capacity | 5000 | Tons |

| Number of Employees | 250 | Persons |

| Energy Consumption | 300000 | kWh |

| Water Usage | 100000 | Liters |

| Waste Produced | 200 | Tons |

Related Products