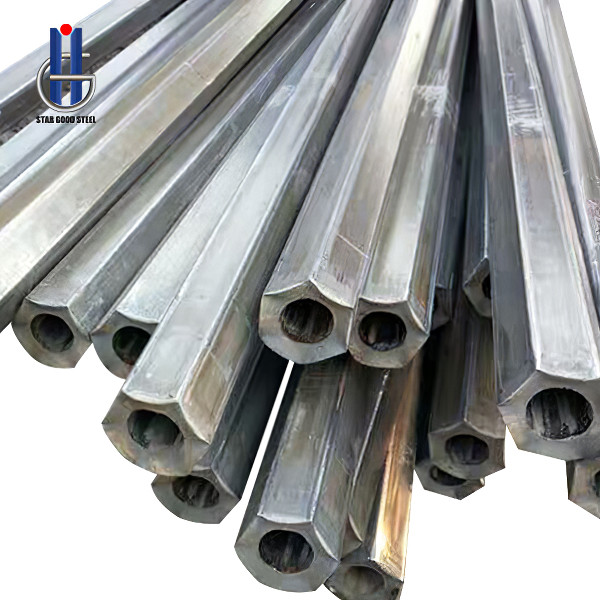

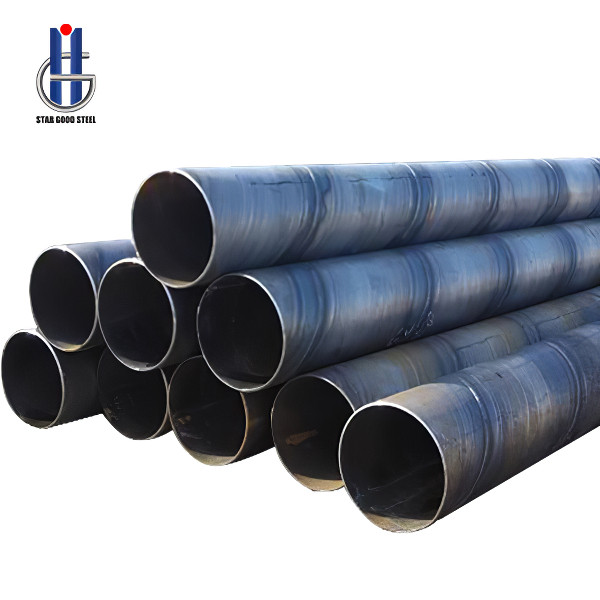

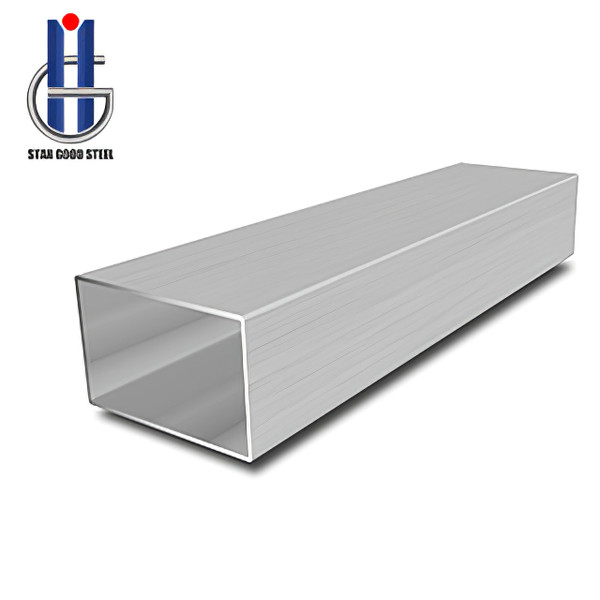

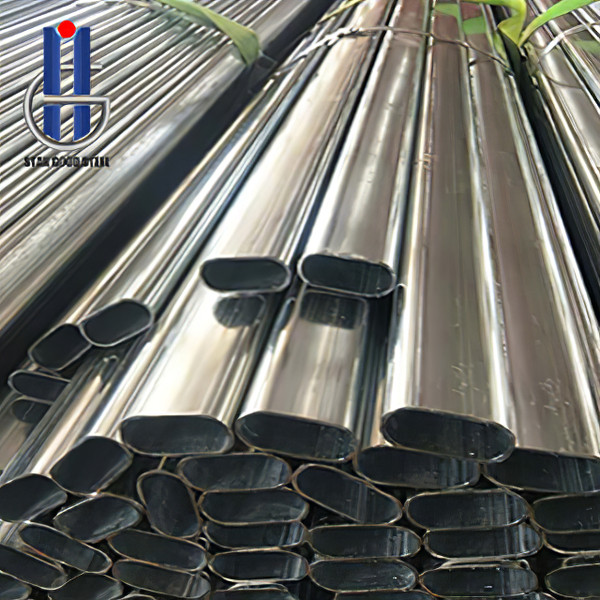

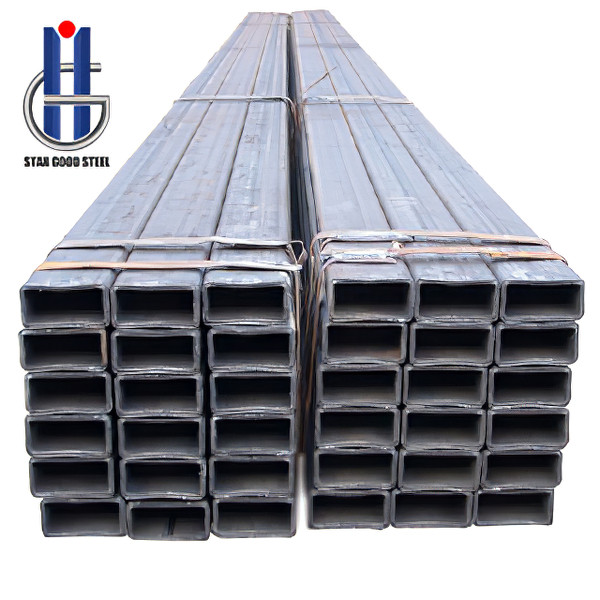

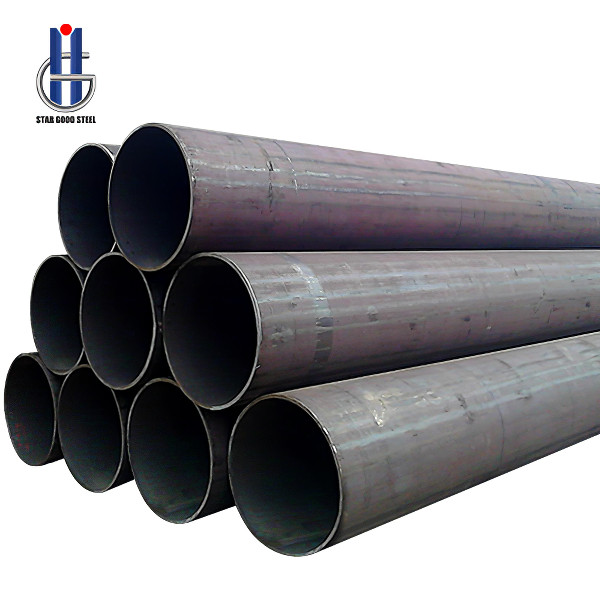

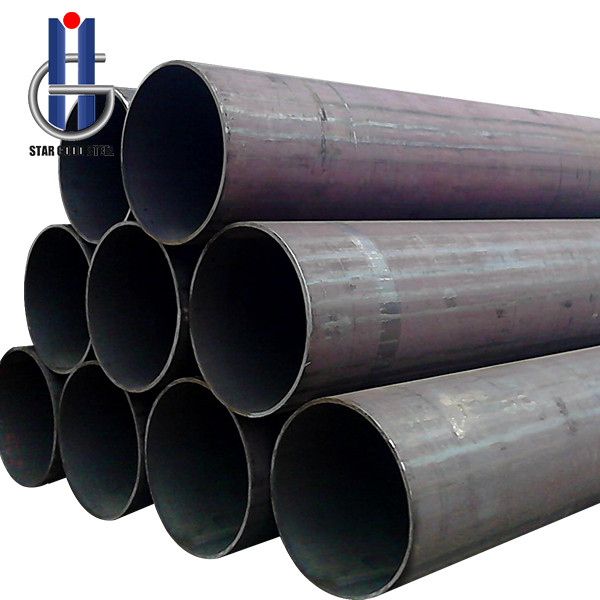

Top China Manufacturer of Quality Steel Tubes for All Applications

When it comes to sourcing high-quality steel tubes, I know the importance of finding a reliable manufacturer. Our offering captures the strength and durability that buyers like you expect. Sourced from trusted facilities in China, these steel tubes are perfect for a variety of applications, whether it’s construction or manufacturing. I understand how crucial it is to have materials that meet stringent quality standards. Our steel tubes go through rigorous testing to ensure they perform under pressure and resist corrosion. Plus, with competitive pricing and customizable options, we make sure your unique project needs are met. If you’re looking to partner with a manufacturer that values quality and service, let’s connect. I’m here to help you find the right steel tube solutions that drive your business forward. With us, you’re not just getting a product; you’re gaining a trusted partner in your supply chain.

Steel Tube in 2025 Pioneers in the Field

As we look toward 2025, the steel tube industry is poised for transformative advancements that will redefine global procurement strategies. With the increasing demand for durable and versatile materials across various sectors, steel tubes are becoming essential components in construction, automotive, and energy industries. These products offer not only strength and resilience but also enhanced performance characteristics, catering to the evolving needs of modern projects. Innovation will play a critical role in shaping the future of steel tube production. Emerging technologies such as automation and smart manufacturing are expected to streamline processes, improve quality, and reduce waste. Furthermore, sustainable practices are gaining traction, with an emphasis on producing eco-friendly steel tubes that meet stringent environmental standards. Global buyers can anticipate a wider range of products that not only fulfill their operational requirements but also align with sustainability goals. In this dynamic landscape, collaboration between manufacturers and buyers will be more crucial than ever. Understanding regional market demands and leveraging advanced logistics solutions will facilitate timely access to top-quality steel tubes. By embracing these changes and fostering strong partnerships, stakeholders can navigate the complexities of the global supply chain, ensuring that they remain at the forefront of the steel tube industry as we move into 2025 and beyond.

Steel Tube in 2025 Pioneers in the Field

| Material Type | Application | Coating Type | Diameter (mm) | Thickness (mm) | Strength (MPa) |

|---|---|---|---|---|---|

| Carbon Steel | Construction | Galvanized | 60 | 3 | 250 |

| Alloy Steel | Automotive | Painted | 75 | 4 | 300 |

| Stainless Steel | Oil & Gas | Passivated | 50 | 2 | 450 |

| Cold Rolled Steel | Aerospace | Coated | 30 | 1.5 | 400 |

Related Products