Cold Drawn Tubes from China Manufacturer - Quality & Durability Guaranteed

When it comes to sourcing high-quality cold drawn tubes, I understand how crucial it is to find a reliable manufacturer, especially in China. Our cold drawn tubes are crafted with precision and designed to meet stringent industry standards. With a focus on strength and durability, these tubes are suitable for various applications, including automotive, construction, and machinery. I take pride in our commitment to quality and customer satisfaction. Working directly with us means you’ll benefit from our extensive experience and expertise in the industry. Plus, our competitive pricing ensures you get the best value without sacrificing performance. Let’s streamline your supply chain together. If you’re looking for a trusted partner for cold drawn tubes, I would love to discuss how we can meet your specific needs and help your business thrive. Reach out today, and let's get started on your next project!

Cold Drawn Tubes Where Service Meets Innovation Outperforms the Competition

In today’s competitive market, the demand for high-quality cold drawn tubes is ever-increasing, as industries seek materials that not only meet their specifications but also enhance their operational efficiency. Cold drawn tubes offer exceptional strength and precision, making them a preferred choice for various applications, including automotive, construction, and manufacturing. By focusing on innovative processes, manufacturers can ensure that their products not only comply with stringent quality standards but also outperform the competition in terms of durability and functionality. Innovation in the production of cold drawn tubes involves employing advanced technologies and techniques that refine the material properties and improve the overall production efficiency. By integrating state-of-the-art machinery and adopting rigorous quality control protocols, the production process can be streamlined to minimize waste while ensuring a consistent supply of top-quality products. This commitment to innovation not only boosts the competitive edge but also fosters a strong relationship with global buyers, ensuring they receive materials that can drive their projects forward. Moreover, a strong service-oriented approach complements innovation, creating a robust framework that supports clients throughout their purchasing journey. By providing tailored solutions, timely delivery, and responsive support, customers can feel secure in their decision to invest in products that will meet their specific needs. Ultimately, the fusion of innovative manufacturing techniques with exceptional customer service sets a benchmark in the industry, allowing for sustained growth and success in the global market for cold drawn tubes.

Cold Drawn Tubes Where Service Meets Innovation Outperforms the Competition

| Dimension (mm) | Material | Application | Tensile Strength (MPa) | Delivery Time (Weeks) |

|---|---|---|---|---|

| 20 x 3 | Stainless Steel | Hydraulic Systems | 580 | 8 |

| 25 x 4 | Carbon Steel | Automotive | 620 | 10 |

| 30 x 5 | Alloy Steel | Construction | 700 | 12 |

| 35 x 6 | Nickel Alloy | Aerospace | 750 | 14 |

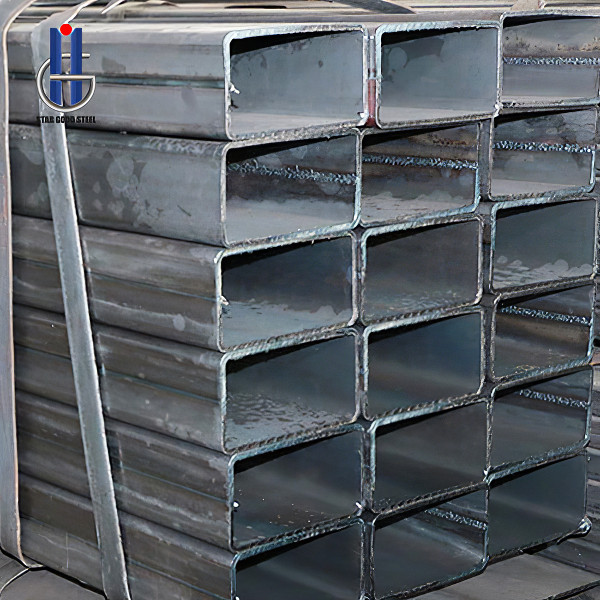

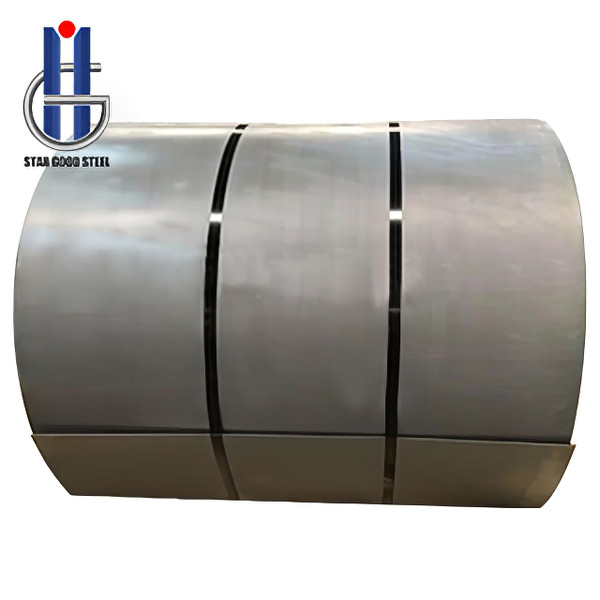

Related Products