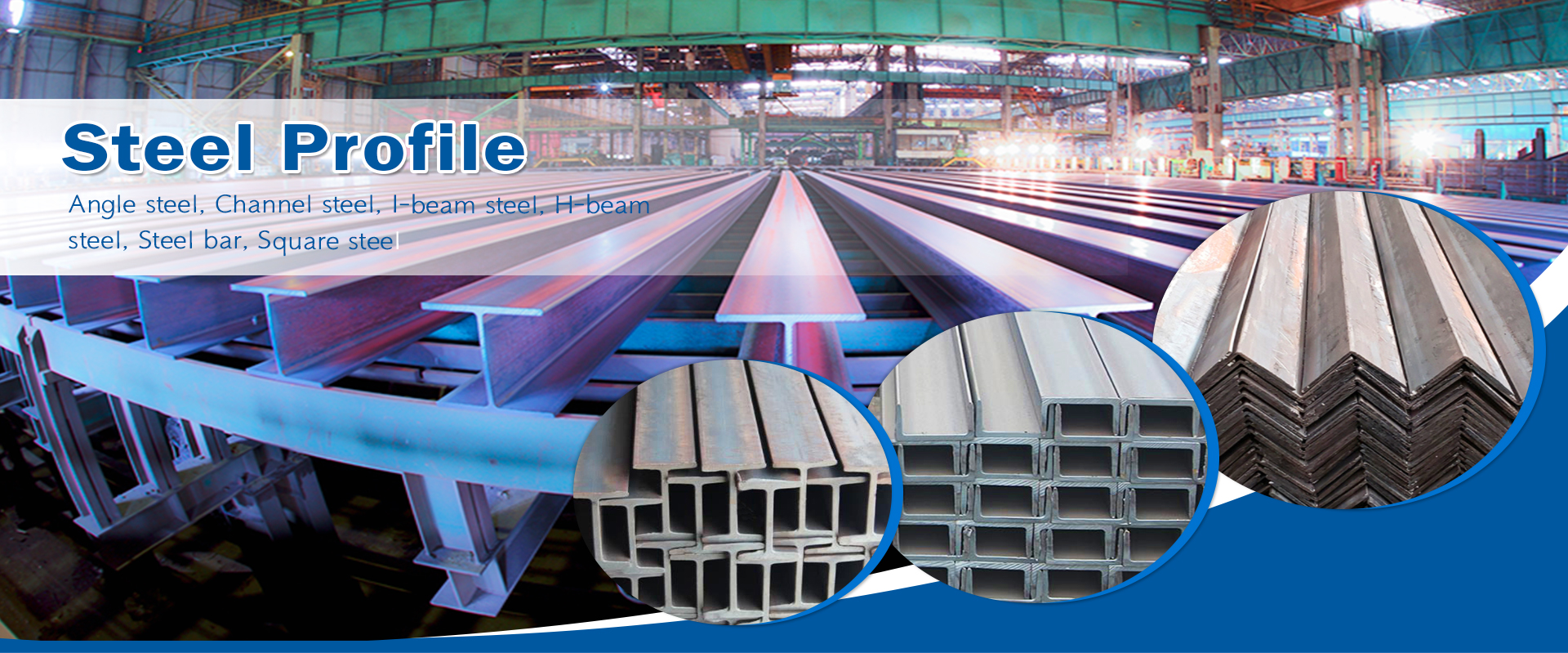

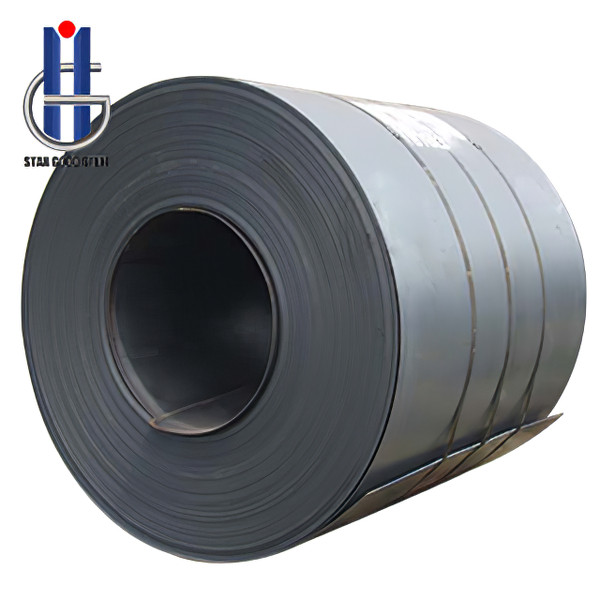

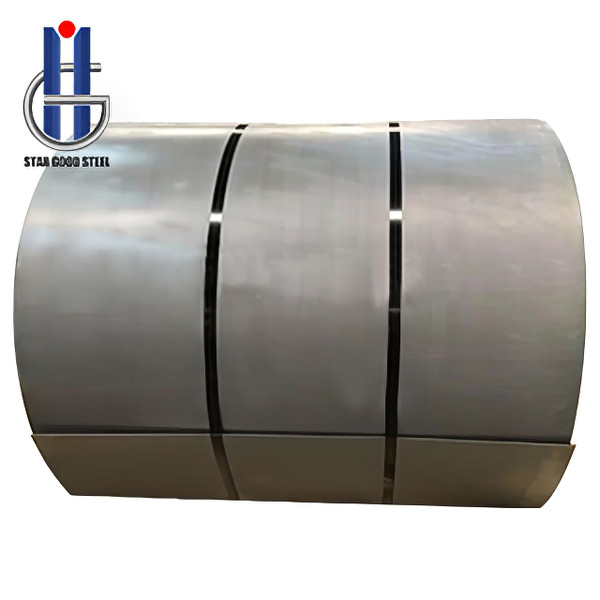

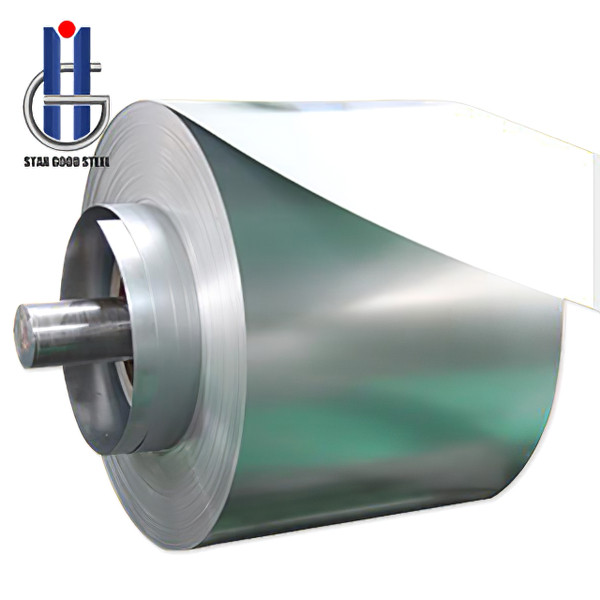

Hot Dipped Galvanized Steel Coil Manufacturer in China for Quality Supply

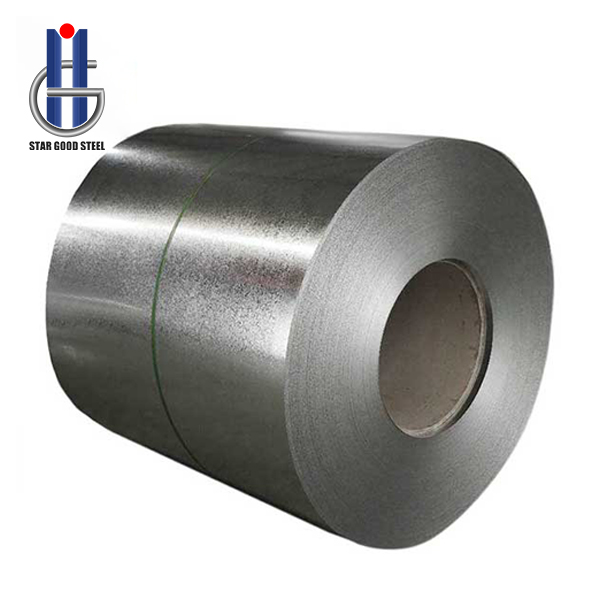

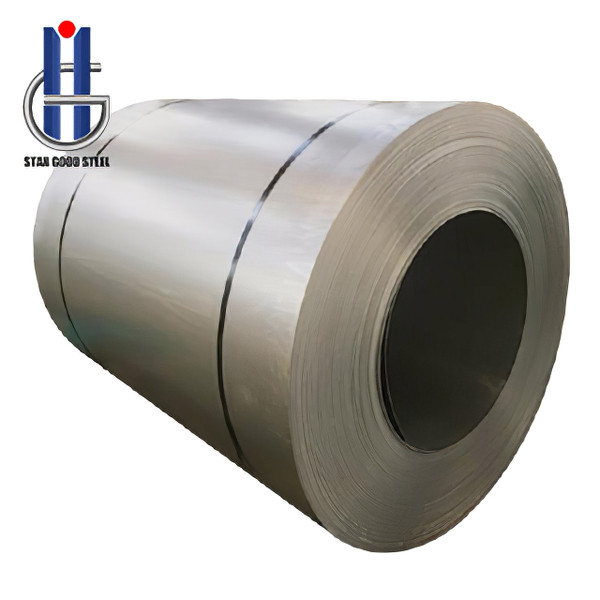

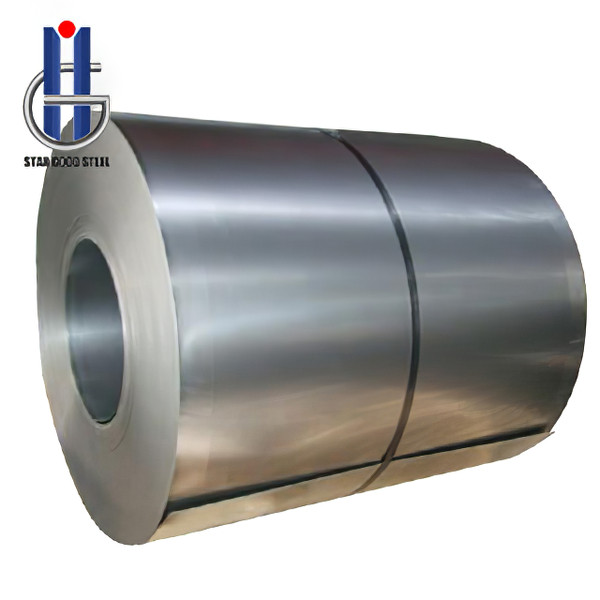

I offer high-quality Hot Dipped Galvanized Steel Coil, perfect for various industrial applications. Sourced from top manufacturers in China, our steel coils are treated to withstand corrosion, ensuring longevity and durability in any setting. Whether you’re in construction, automotive, or any other sector that relies on robust materials, our products fit the bill. You’ll find that our coils are not only competitively priced but also maintain strict quality standards that meet international norms. This means you can trust in the reliability and performance of each batch we supply. With our dedicated support team, I am here to answer any questions you might have about specifications, shipment timelines, or pricing. Choosing Hot Dipped Galvanized Steel Coil from us means investing in quality that lasts. Let’s work together to meet your project needs and exceed your expectations. Don’t hesitate to reach out for more information!

Hot Dipped Galvanized Steel Coil Application Service

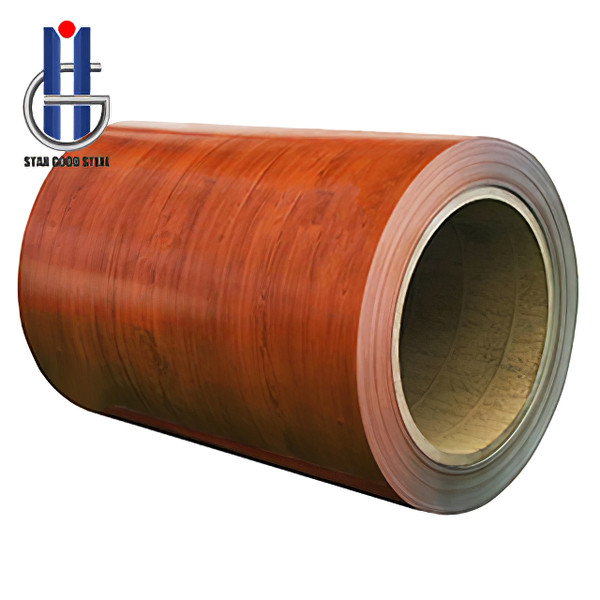

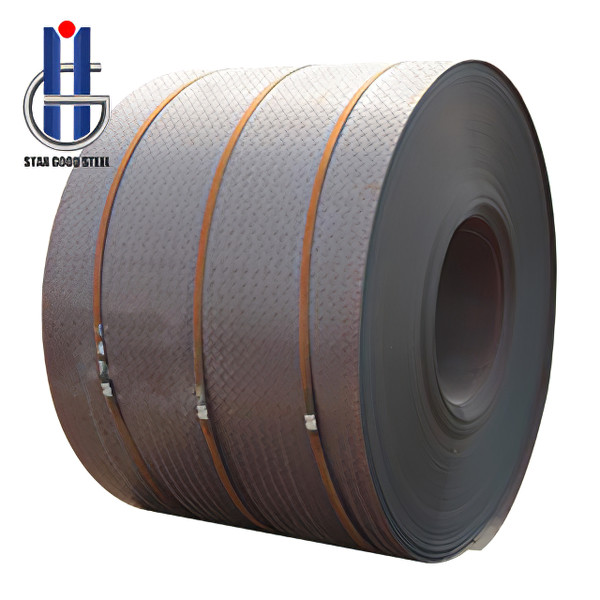

Hot dipped galvanized steel coils are rapidly becoming the go-to choice for industries seeking durability and corrosion resistance. These coils are produced by immersing steel sheets in molten zinc, creating a robust barrier that protects against rust and environmental wear. The versatility of hot dipped galvanized steel makes it suitable for a wide range of applications, including construction, automotive manufacturing, and home appliances. As global demand for reliable and resilient materials increases, the application possibilities for these steel coils continue to expand. In the construction industry, hot dipped galvanized steel coils are utilized for roofing materials, siding, and structural components, ensuring long-lasting performance even in harsh weather conditions. Similarly, in automotive manufacturing, they provide essential durability for vehicle components, enhancing safety and longevity. The home appliance sector also benefits from these steel coils, as they ensure that products maintain their integrity over time, leading to lower replacement rates and ultimately, cost savings for consumers. With the growing emphasis on sustainability and efficiency, businesses are increasingly recognizing the value of integrating hot dipped galvanized steel into their supply chains. This material not only stands up to the challenges of various environments but also contributes to overall cost-effectiveness by reducing maintenance needs. As industries across the globe continue to prioritize quality and longevity in their manufacturing processes, hot dipped galvanized steel coils emerge as a clear choice for those looking to secure a competitive edge in today’s market.

Hot Dipped Galvanized Steel Coil Application Service

| Application | Industry | Advantages | Common Thickness (mm) | Typical Width (mm) |

|---|---|---|---|---|

| Construction | Building Materials | Corrosion Resistance | 0.3 - 3.0 | 600 - 1250 |

| Automotive | Automotive Manufacturing | Durability and Strength | 0.5 - 2.5 | 800 - 1500 |

| Electrical | Electrical Appliances | High Conductivity | 0.4 - 2.0 | 500 - 1200 |

| Agriculture | Agricultural Equipment | Weather Protection | 0.5 - 3.0 | 700 - 1400 |

| Furniture | Home Furnishings | Aesthetic Appeal | 0.5 - 2.0 | 400 - 1000 |

Related Products