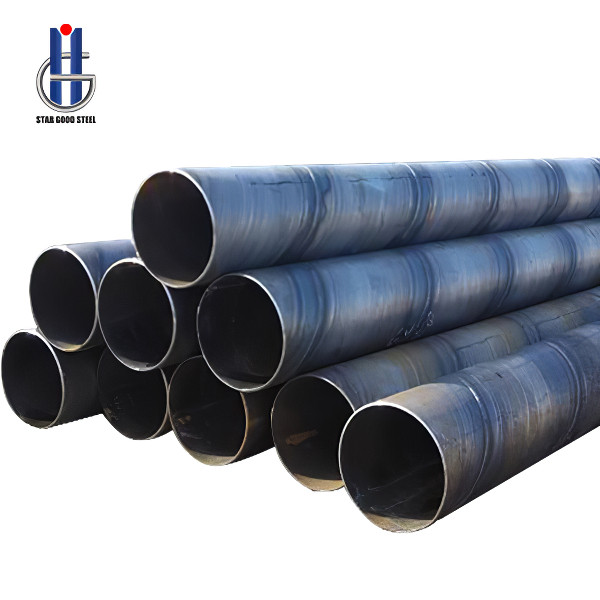

Top China Manufacturer of High-Quality Spiral Steel Tubes

As a leading manufacturer of Spiral Steel Tubes in China, I take pride in offering high-quality products that meet diverse industry needs. Our Spiral Steel Tubes are designed for superior strength and durability, making them ideal for applications in construction, automotive, and energy sectors. I understand that B2B purchasers like you seek reliable solutions, and that's why we focus on precision engineering and quality control throughout the manufacturing process. With a commitment to outstanding customer service, I make sure every order, large or small, is fulfilled efficiently. When you choose our Spiral Steel Tubes, you’re not just getting a product; you’re investing in a reliable partnership that supports your business objectives. Let's elevate your projects together with our state-of-the-art spiral tubular solutions. Contact me today to learn more about how our products can fit your requirements!

Spiral Steel Tube Factory From Concept to Delivery

In today's fast-paced industrial landscape, the journey from concept to delivery of spiral steel tubes is critical for manufacturers and global procurement professionals alike. Spiral steel tubes are renowned for their strength, versatility, and ability to meet various application requirements, making them a valuable addition to construction, infrastructure, and many other sectors. The manufacturing process begins with careful design considerations, where engineers collaborate with clients to ensure that the final product meets the specific needs of their projects. As the production commences, attention to detail is paramount. Advanced technology and skilled labor converge to create tubes that undergo rigorous quality control measures throughout the manufacturing stages. From the selection of high-quality raw materials to intricate welding techniques, every step is designed to uphold the highest industry standards. This meticulous process not only guarantees product performance but also fosters trust between manufacturers and procurement partners. Once production is complete, the focus shifts to logistics and delivery. Efficient transportation solutions are essential to ensure that the products reach clients in a timely manner, minimizing downtime and facilitating smooth project execution. Comprehensive support doesn’t end with delivery; ongoing communication helps address any issues that may arise, ensuring long-term satisfaction and fostering enduring partnerships. For global procurement professionals seeking reliable sources for spiral steel tubes, understanding this journey is key to making informed decisions that drive project success.

Spiral Steel Tube Factory From Concept to Delivery

| Stage | Description | Duration | Key Deliverables |

|---|---|---|---|

| Conceptualization | Develop initial design and specifications. | 2 weeks | Design documents, project plan |

| Material Selection | Select appropriate steel grades and materials. | 1 week | Material specifications, supplier list |

| Manufacturing | Production of spiral steel tubes using selected materials. | 4 weeks | Finished products, quality assurance reports |

| Testing | Perform quality and safety tests on completed products. | 1 week | Test results, certification documents |

| Delivery | Package and ship products to customers. | 1 week | Shipping documents, tracking information |

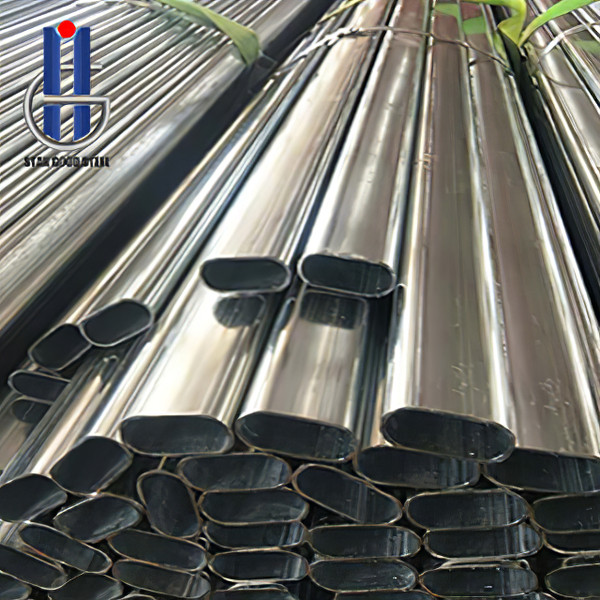

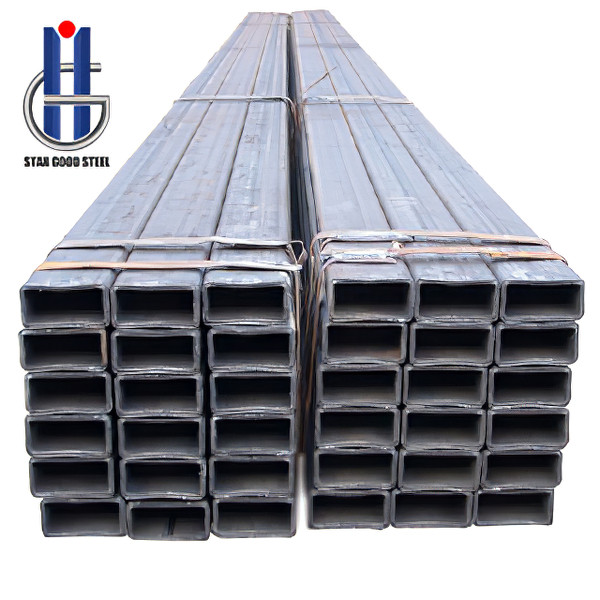

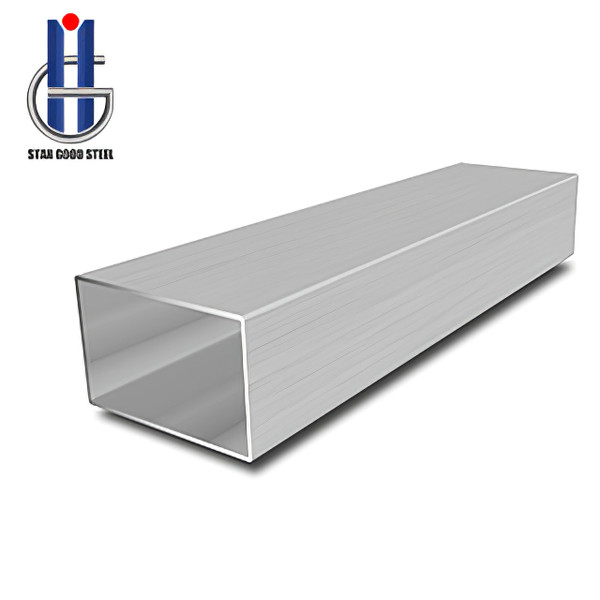

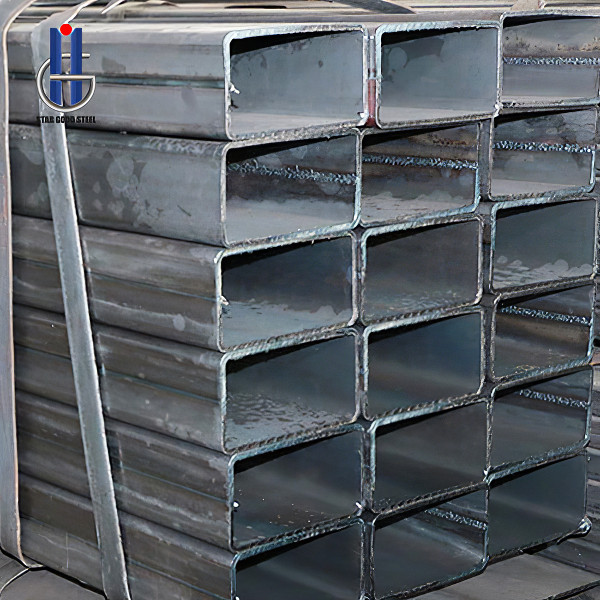

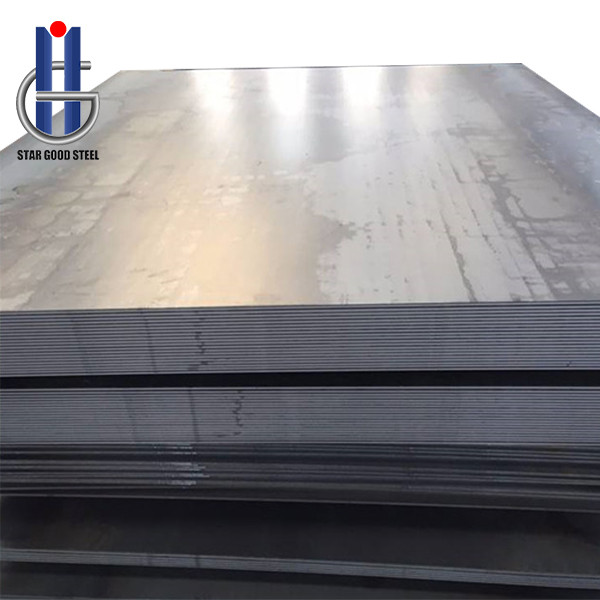

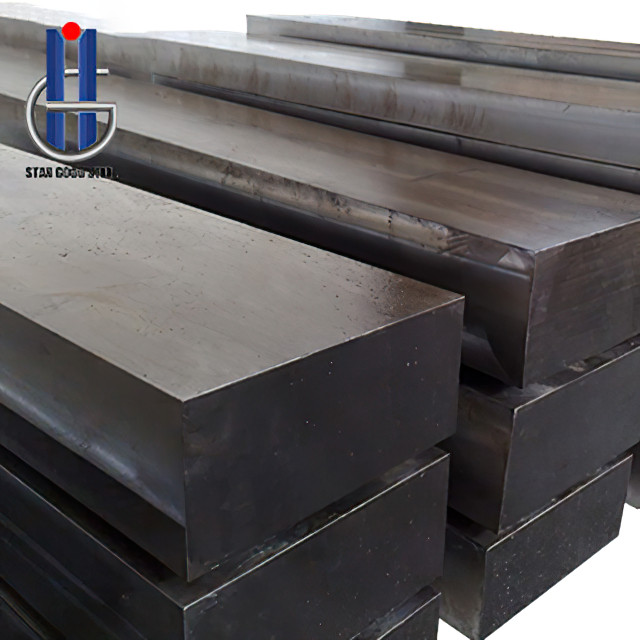

Related Products