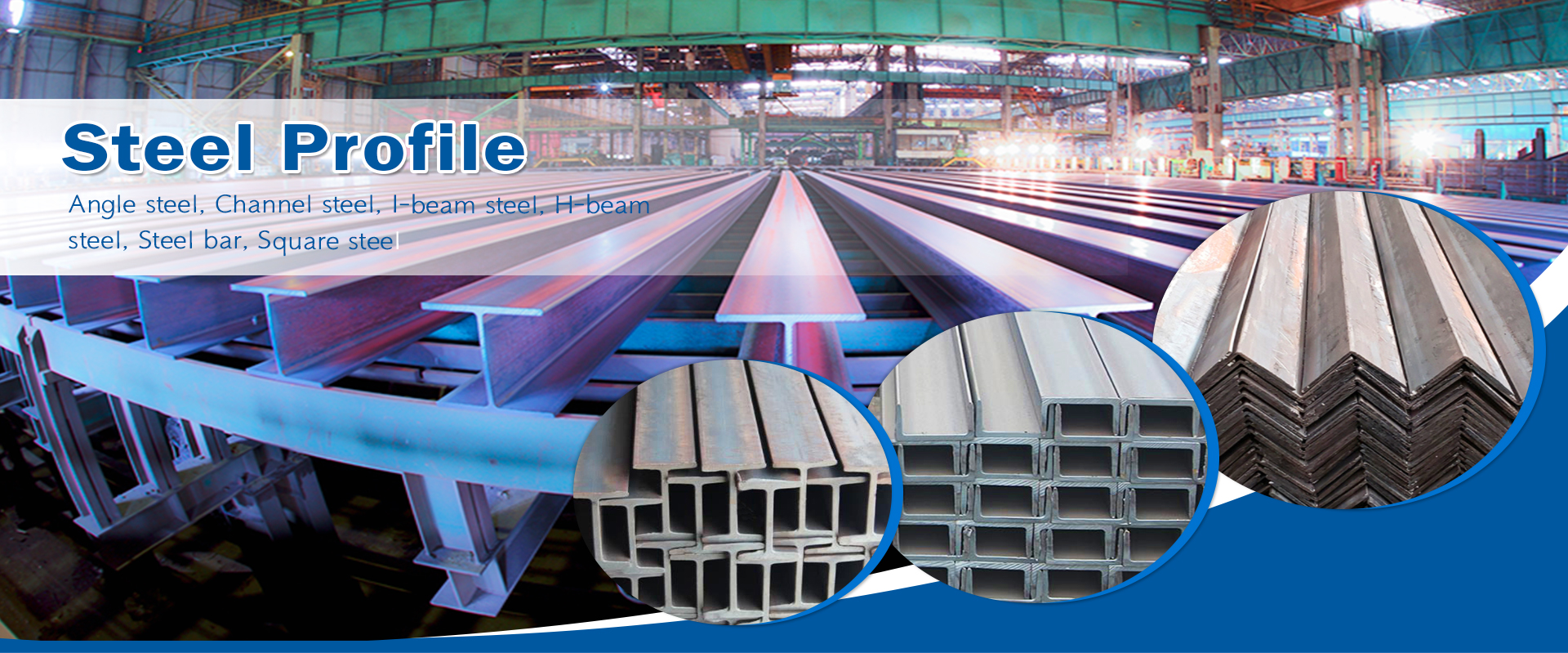

Top China Manufacturer of Stainless Steel Tube Processing Plant Solutions

At our Stainless Steel Tube Processing Plant, I pride myself on offering high-quality manufacturing solutions tailored for your business needs. As a leading manufacturer in China, we understand the demands of various industries and aim to deliver precision-engineered stainless steel tubes that meet global standards. Our advanced processing capabilities allow us to customize dimensions and finishes, ensuring you get exactly what you require for your projects. I take great care in maintaining strict quality controls throughout the production process, so you can trust that our products will perform reliably even in the toughest environments. Whether you're involved in construction, automotive, or any sector that relies on superior stainless steel products, partnering with us means you’ll have access to a robust supply chain and competitive pricing. Let’s work together to elevate your operations with our expert solutions in stainless steel tube processing.

Stainless Steel Tube Processing Plant Exceeds Industry Benchmarks Manufacturers You Can Rely On

In the competitive landscape of stainless steel tube manufacturing, efficiency and quality are paramount. A state-of-the-art processing plant that exceeds industry benchmarks not only ensures superior product offerings but also emphasizes a commitment to innovation and sustainability. Advanced machinery, coupled with skilled craftsmanship, positions manufacturers at the forefront of the industry, enabling them to produce a wide array of stainless steel tubes tailored to various applications. Global procurement specialists seeking reliable partners can benefit from such manufacturers who prioritize precision in every phase of production. From seamless tubes for hydraulic applications to welded options for structural integrity, the manufacturing processes employed lead to the creation of products that meet and surpass international standards. Moreover, commitment to sustainability through eco-friendly practices enhances the overall efficiency of operations, making these manufacturers favorable choices for environmentally-conscious clients. As industries evolve and demand for high-quality stainless steel products rises, collaboration with manufacturers that embrace cutting-edge technology and uphold rigorous quality control measures becomes a strategic advantage. Trustworthy partnerships foster innovation, driving the development of new solutions and ensuring that procurement needs are met with excellence. When sourcing stainless steel tubes, aligning with a manufacturer known for exceeding benchmarks is more than a choice—it's a competitive edge.

Stainless Steel Tube Processing Plant Exceeds Industry Benchmarks Manufacturers You Can Rely On

| Manufacturer | Production Capacity (tons/year) | Quality Standard | Certifications | Lead Time (weeks) | Customer Satisfaction Rating |

|---|---|---|---|---|---|

| Manufacturer A | 1500 | ASTM A554 | ISO 9001, CE | 6 | 4.8/5 |

| Manufacturer B | 1000 | ASME SA269 | ISO 14001 | 8 | 4.5/5 |

| Manufacturer C | 2000 | EN 10217 | ISO 45001 | 5 | 4.9/5 |

| Manufacturer D | 1200 | ISO 1127 | TUV | 7 | 4.6/5 |

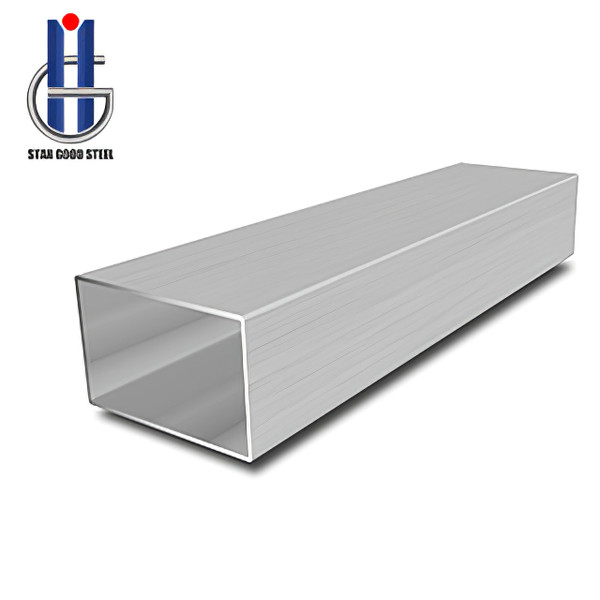

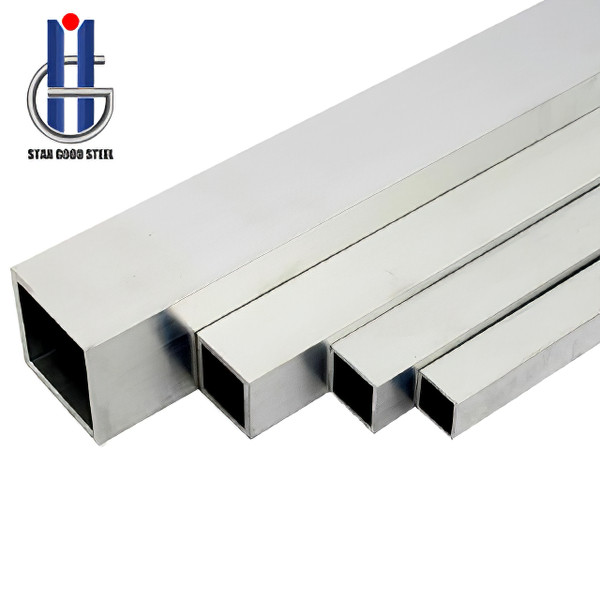

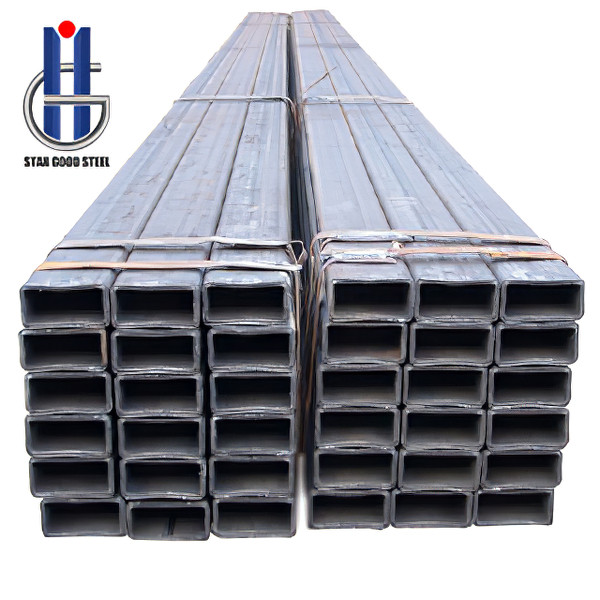

Related Products